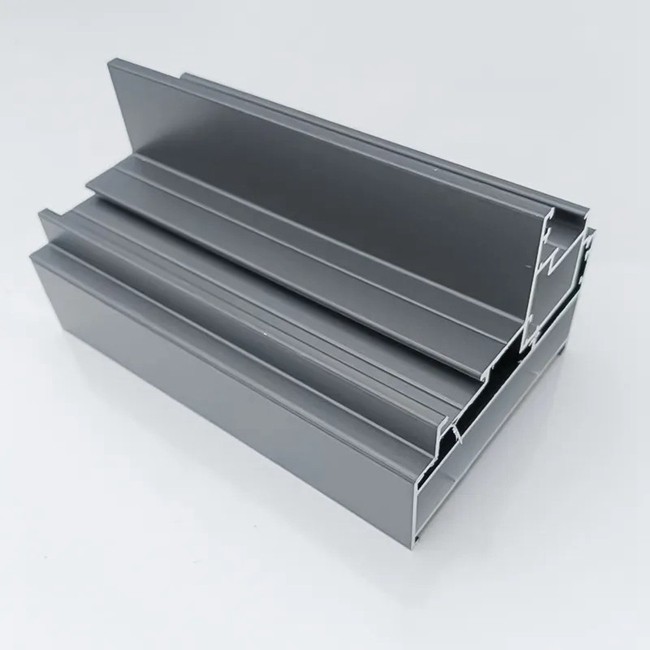

The manufacturer customizes high-quality aluminum alloy profiles

Product description

Aluminum alloy profiles represent a pinnacle of material science, combining the lightweight versatility of aluminum with enhanced mechanical properties tailored for industrial, architectural, and technological applications. These profiles, formed through precision extrusion and alloying, have become indispensable in sectors demanding strength, durability, and design adaptability. This article explores the science behind aluminum alloys, their manufacturing processes, unique advantages, and transformative role across industries.

Understanding Aluminum Alloys

Aluminum alloys are created by blending pure aluminum with elements such as magnesium, silicon, copper, zinc, or manganese. These additions refine the metal’s properties, improving strength, corrosion resistance, thermal conductivity, and machinability. Common alloy series used in profiles include:

6xxx Series (e.g., 6061, 6063):

Magnesium and silicon are key components, offering excellent corrosion resistance, weldability, and moderate strength. It is ideal for architectural and structural applications.

7xxx Series (e.g., 7075):

Zinc-dominated alloys with exceptional strength-to-weight ratios, often used in aerospace and high-stress environments.

5xxx Series (e.g., 5083):

Magnesium-rich alloys known for superior marine-grade corrosion resistance.

Each alloy is heat-treated (e.g., T6 tempering) to achieve optimal mechanical performance.

Manufacturing Process: Precision Meets Customization

Aluminum alloy profiles are produced via extrusion, a process that balances efficiency with design flexibility:

Billet Preparation:

Cylindrical aluminum alloy billets are heated to 450–500°C to soften the metal.

Extrusion:

The billet is forced through a die using hydraulic pressure, shaping it into continuous profiles with complex cross-sections.

Cooling and Straightening:

Rapid quenching (air or water) locks in the alloy’s microstructure, followed by stretching to eliminate distortions.

Surface Treatment:

Anodizing, powder coating, or mechanical finishing enhances aesthetics, corrosion resistance, and durability.

This process allows for mass production of standardized profiles or bespoke designs tailored to niche applications.

Key Advantages of Aluminum Alloy Profiles

Superior Strength-to-Weight Ratio:

Alloying boosts aluminum’s strength while retaining its lightweight nature—critical for aerospace, automotive, and transportation industries.

Corrosion Resistance:

Alloys like 6061 and 5083 develop protective oxide layers, resisting rust in humid, saline, or chemically aggressive environments.

Thermal and Electrical Conductivity:

Retain aluminum’s natural conductivity, making it ideal for heat sinks, electrical enclosures, and energy-efficient building systems.

Design Freedom:

Complex geometries—hollow chambers, multi-void structures, or integrated grooves, are extruded in a single pass, reducing steps assembly.

Recyclability:

Aluminum alloys retain their properties indefinitely through recycling, supporting circular economy goals. Over 70% of aluminum ever produced remains in use today.

Cost Efficiency:

High-speed extrusion and minimal post-processing lower production costs compared to steel or titanium.

Applications Across Industries

Aerospace:

High-strength 7xxx alloys form aircraft frames, wing supports, and satellite components, reducing weight without compromising safety.

Automotive:

Lightweight 6xxx profiles are used in electric vehicle (EV) battery housings, chassis, and body panels to enhance range and efficiency.

Construction:

Structural beams, curtain walls, and solar panel frameworks leverage 6063’s balance of strength and corrosion resistance.

Electronics:

Heat-dissipating profiles in LED lighting, CPU coolers, and 5G infrastructure ensure thermal management in compact designs.

Industrial Machinery:

Custom alloy extrusions create modular conveyor systems, robotic arms, and machine guards resistant to wear and vibration.

Innovations Driving the Future

Nano-Structured Alloys:

Advanced metallurgy techniques produce ultra-fine grain structures, enhancing strength and fatigue resistance.

Additive Manufacturing:

3D-printed aluminum alloy profiles enable rapid prototyping of complex geometries unachievable via traditional extrusion.

Smart Alloys:

Integration of sensors or phase-change materials within profiles for real-time structural health monitoring or adaptive thermal regulation.

Green Alloys:

Development of low-carbon aluminum alloys using renewable energy and recycled content to meet sustainability targets.

Challenges and Solutions

While aluminum alloys excel in many areas, challenges persist:

Galvanic Corrosion:

When coupled with dissimilar metals (e.g., steel), galvanic corrosion can occur. Solutions include insulating coatings or using compatible alloys.

Cost of High-Performance Alloys:

Aerospace-grade alloys (e.g., 7075) are expensive. Advances in recycling and production scaling aim to reduce costs.

About Us

FOSHAN XINWEI ALUMINUM Co., Ltd. is a professional manufacturing enterprise that mainly produces industrial and household aluminum profiles and products. It has a team of experienced technical staff and efficient managerial staff. It is also equipped with 6 advanced aluminum extrusion lines and quality control equipment to ensure first-class products to be produced.

The whole production process includes: Aluminum ingot casting, extrusion mold design and making, extruding, aging treatment, surface treatment (including sandblasting, anodizing, powder coating and spraying. What′s more, we have already got the ISO9001 Quality Management System and ISO14001 Environmental Management System certifications.

We produce more than 2500 items of construction and industrial profiles, windows and doors, and household products. The manufacturing capability of company reaches 10000 tons a year. 90% of our products are mainly sold to overseas markets such as Europe, North America, Africa, Southeast Asia, HK, and Macao. At the same time, our company is nominated as approved supplier of several multinational corporations.

We are ready to make all kinds of aluminum alloy profiles and products according to customers′ samples or drawings to meet the demand of markets.

Recommended products