Plastic Recycling Granulator Machine: A Comprehensive Guide

Product description

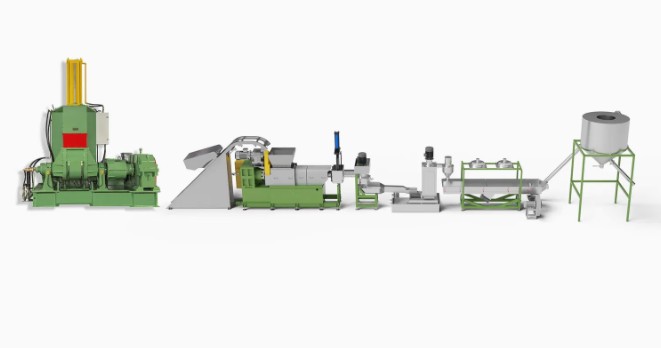

A plastic recycling granulator machine is a critical piece of equipment in the waste management and recycling industry. Designed to shred, grind, and process plastic scraps into uniform granules, this machine transforms discarded plastics (e.g., bottles, containers, industrial waste, or defective products) into reusable raw materials. These granules are ideal for manufacturing new plastic products, reducing environmental pollution, and minimizing reliance on virgin plastics. Modern granulators are engineered for efficiency, durability, and adaptability, making them essential for businesses aiming to adopt sustainable practices.

Key Features of Plastic Recycling Granulator Machines

High-Speed Cutting System

Equipped with precision-engineered blades and a powerful motor, the machine rapidly processes plastics into small and uniform particles.

Adjustable blade speed accommodates different material types and thicknesses.

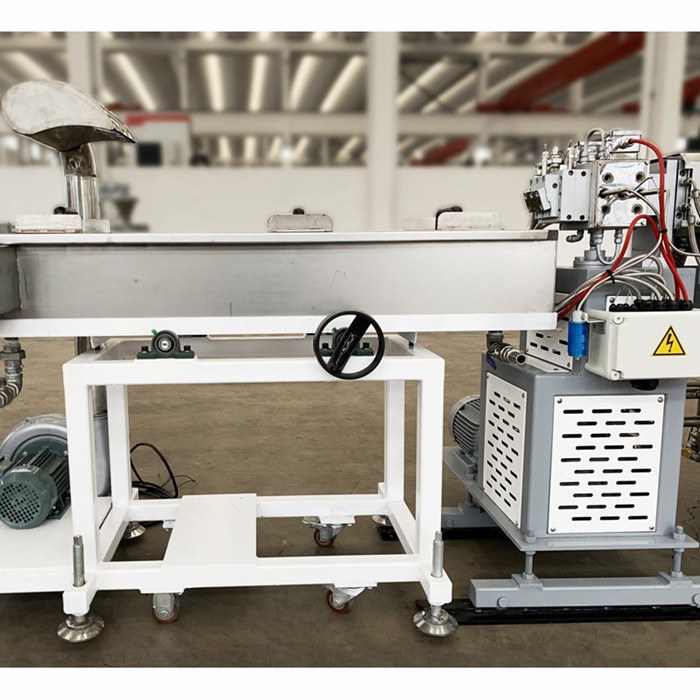

Robust Construction

Made from hardened steel or wear-resistant alloys, the machine withstands heavy-duty use and abrasive materials.

Anti-corrosion coatings extend lifespan in harsh environments.

Versatile Material Compatibility

Process a wide range of plastics, including PE, PP, PVC, PET, ABS and more.

Handle both rigid (e.g., pipes, buckets) and flexible plastics (e.g., films, bags).

Customizable Output Size

Interchangeable mesh screens allow users to control granule size (typically 2–10 mm) based on application requirements.

Energy Efficiency

Advanced models feature energy-saving motors and intelligent controls to minimize power consumption.

Safety Mechanisms

Emergency stop buttons, overload protection, and safety interlocks ensure operator safety.

Applications of Plastic Granulator Machines

Plastic granulators are utilized across diverse industries:

Recycling Plants: Convert municipal or industrial plastic waste into granules for reuse.

Manufacturing Facilities: Recycle production scraps (e.g., sprues, rejected parts) from injection molding or extrusion lines.

Packaging Industry: Process post-consumer packaging waste like bottles, films, and containers.

Automotive Sector: Recycle plastic components (e.g., dashboards, bumpers) and synthetic fiber waste.

Agriculture: Repurpose used agricultural films, irrigation pipes, and seedling trays.

Q1: What types of plastics can a granulator machine process?

A1: Most granulators handle common plastics like PE, PP, PVC, PET, and ABS. However, materials with high melting points (e.g., nylon) or excessive hardness may require specialized blades. Always check the machine’s specifications for compatibility.

Q2: How do I maintain the blades for optimal performance?

A2: Regularly inspect blades for wear and tear. Sharpen or replace them every 300–800 operating hours, depending on material abrasiveness. Clean blades after use to prevent residue buildup.

Q3: Can the machine process wet or dirty plastic waste?

A3: No. Wet or contaminated plastics (e.g., food residue, sand) can damage blades and reduce output quality. Pre-wash and dry materials before granulation.

Q4: What safety features should I look for in a granulator?

A4: Prioritize machines with emergency stop buttons, safety locks, overload protection, and noise reduction systems. Operator training is also crucial to prevent accidents.

Q5: How much energy does a plastic granulator consume?

A5: Energy use depends on machine size and workload. Small-scale models may require 5–15 kW/h, while industrial units consume 30–100 kW/h. Energy-efficient models with variable frequency drives (VFDs) can reduce consumption by up to 30%.

Recommended products