The recycled Plastic Granulator Machine is for sale

Product description

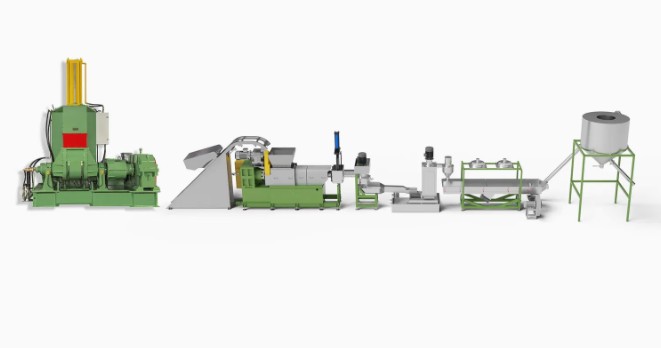

A plastic granulator machine is an industrial device designed to recycle plastic waste into uniform granules, which can then be reused in manufacturing processes. This equipment plays a critical role in the plastic recycling industry, transforming post-consumer or post-industrial plastic scraps (e.g., bottles, films, pipes, or defective products) into raw material pellets. These pellets are compatible with injection molding, extrusion, and other production methods, promoting sustainability and reducing reliance on virgin plastics.

Key Features of Plastic Granulator Machines

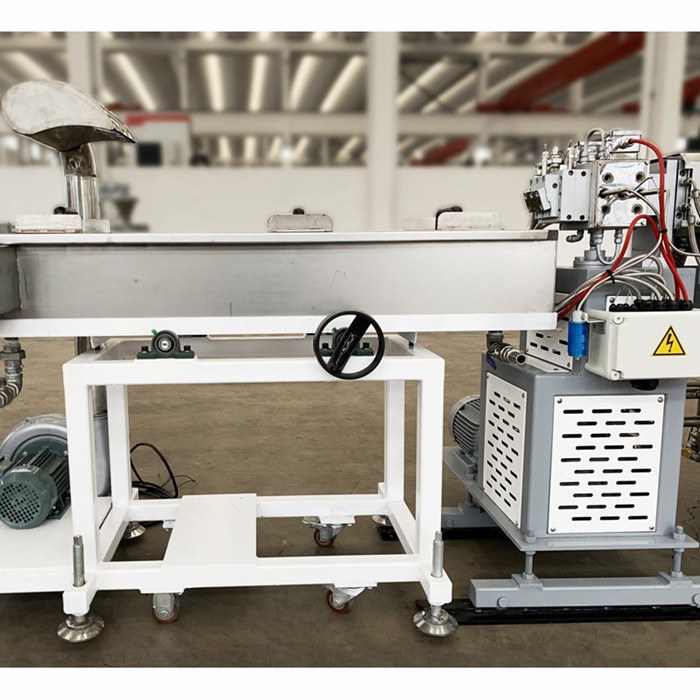

High Efficiency: Equipped with robust blades and motors, these machines process large volumes of plastic waste quickly, ensuring high output with minimal energy consumption.

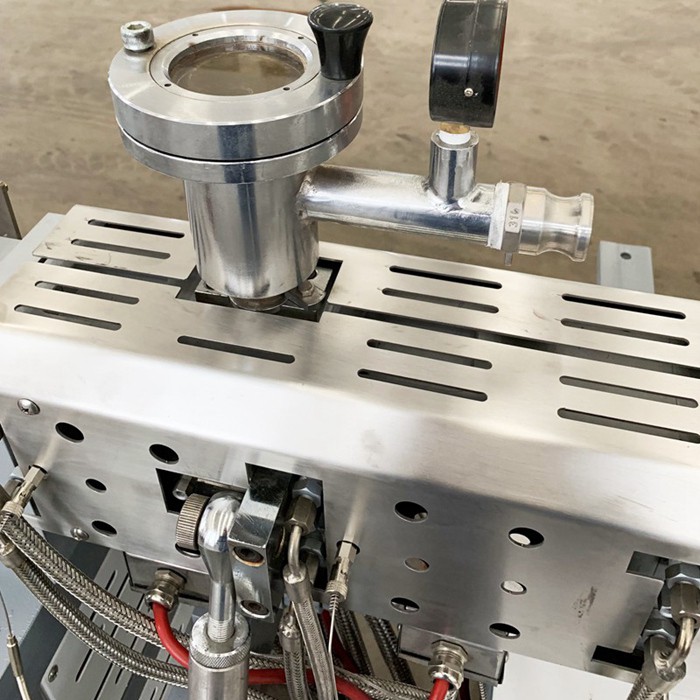

Durable Construction: Made from hardened steel or alloy components, granulators resist wear and tear even when handling abrasive materials.

Versatility: Capable of processing various plastic types, including PE, PP, PVC, PET, and ABS as well as different forms of waste (e.g., rigid, flexible, or mixed plastics).

User-Friendly Design: Features like adjustable blade speed, automated feeding systems, and safety interlocks simplify operation and reduce manual intervention.

Customizable Screen Sizes: Interchangeable screens control the size of the output granules (typically 3–12 mm) tailored to specific production needs.

Applications

Plastic granulator machines are widely used across industries such as:

Recycling Facilities: Convert municipal or industrial plastic waste into reusable pellets.

Manufacturing: Reproduce defective parts or trimmings from injection molding or extrusion lines.

Packaging: Recycle discarded films, containers, or packaging materials.

Textiles and Automotive: Process synthetic fiber waste or plastic components from vehicles.

Q1: Can a granulator handle mixed plastic types?

A1: While some advanced models can process mixed plastics, contamination (e.g., different melting points) may affect output quality. Pre-sorting by polymer type is recommended for optimal results.

Q2: Is pre-washing required for plastic waste?

A2: Yes. Contaminants like dirt, labels, or residues should be removed before granulation to protect blades and ensure clean and high-quality granules.

Q3: How often should blades be maintained or replaced?

A3: Blade lifespan depends on material hardness and usage frequency. Regular inspection is advised; typically, sharpening or replacement is needed every 500–1,000 operating hours.

Q4: Are plastic granulators energy-intensive?

A4: Modern machines prioritize energy efficiency. Consumption varies by model and workload, but many include energy-saving features like variable frequency drives (VFDs) to reduce power use.

Q5: Can the machine produce food-grade recycled pellets?

A5: Only if the input material is food-safe and the granulator is thoroughly cleaned to avoid cross-contamination. Additional certifications (e.g., FDA compliance) may be required.

Recommended products