Exploring the Efficiency and Versatility of Paperboard Machines

Product description

In today’s fast-paced manufacturing industry, the demand for durable, eco-friendly, and cost-effective materials has led to an increased reliance on paperboard as a preferred packaging solution. Paperboard machines play a pivotal role in the production of high-quality paperboard used across various industries from packaging to printing. With over two decades of industry expertise, this article delves into the core features, benefits, and applications of paperboard machines, offering insight into why they are indispensable for modern production lines.

Understanding Paperboard Machines: What Are They?

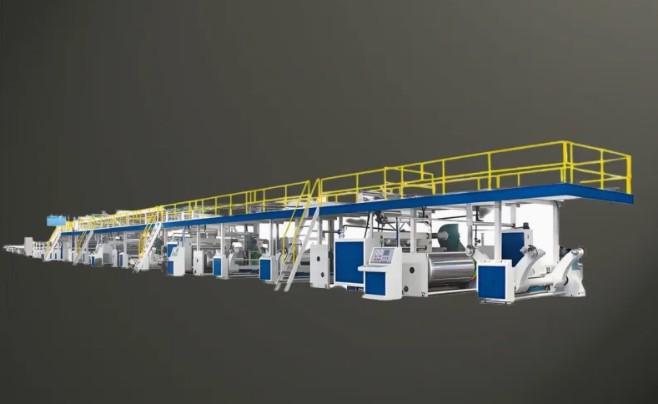

A paperboard machine is an industrial device designed to produce paperboard, a thicker and more durable form of paper that is commonly used for packaging and product containers. These machines are engineered to produce large rolls or sheets of paperboard, often using recycled paper as raw material. The process involves several stages, including pulping, forming, pressing, drying, and reeling the paperboard into large rolls for further processing or direct distribution.

The construction of a paperboard machine involves sophisticated technology that ensures consistent quality and efficiency. These machines come in various configurations, depending on the type of paperboard being produced, whether it’s for high-end packaging or simple corrugated cardboard.

Key Features of Paperboard Machines

1. High Production Capacity: Paperboard machines are built for high throughput, capable of producing large quantities of paperboard in a relatively short period. This feature makes them ideal for high-demand applications particularly in industries like packaging, printing, and consumer goods.

2. Advanced Automation: Modern paperboard machines are equipped with cutting-edge automation features. This includes digital controls for temperature, pressure, and speed adjustments, ensuring optimal performance throughout the production process. Automation not only boosts productivity but also enhances consistency and reduces human error.

3. Energy Efficiency: Given the substantial energy consumption in paper production, many contemporary paperboard machines are designed to be energy-efficient. This is achieved through innovations such as heat recovery systems and optimized drying processes that reduce overall energy usage, making the production process more sustainable.

4. Customization Options: Paperboard machines can be tailored to produce different types of paperboard such as single-ply, double-ply, or coated paperboard. This flexibility allows manufacturers to meet specific customer requirements, whether it's for lightweight packaging or robust and heavy-duty containers.

Benefits of Paperboard Machines

1. Sustainability: As the world moves towards more eco-conscious practices, paperboard is increasingly favored for its recyclable properties. Paperboard machines that utilize recycled fibers contribute to reducing the environmental footprint of packaging materials, making them an essential part of green manufacturing strategies.

2. Cost-Effective Production: Paperboard machines enable manufacturers to produce high volumes of paperboard with minimal labor and material waste. The advanced technology integrated into these machines leads to cost savings over time, making them a wise investment for companies aiming to optimize their production lines.

3. Superior Quality: The precision engineering of modern paperboard machines ensures that the final product meets strict quality standards. From smooth finishes to uniform thickness, the high-quality output enhances the appearance and functionality of the paperboard, whether it’s used for packaging premium products or creating displays that demand attention.

4. Versatility in Applications: Paperboard produced by these machines finds a wide range of applications across various sectors. In the packaging industry, paperboard is used for everything from food containers and beverage cartons to retail packaging and shipping boxes. Its strength and flexibility also make it ideal for printing purposes, including the creation of brochures, business cards, and promotional materials.

Primary Applications and Industries Served

Paperboard machines serve diverse industries where the need for durable, sustainable, and cost-effective packaging solutions is paramount. These include:

1. Packaging: Manufacturers of consumer goods rely heavily on paperboard for packaging from food products to electronics and cosmetics. The ability to customize the thickness and finish of the paperboard makes it a versatile solution for a wide range of packaging needs.

2. Printing: Paperboard’s smooth surface makes it an excellent choice for printing high-quality graphics and text. Whether it’s for marketing materials, product packaging, or informational brochures, paperboard provides a reliable medium for delivering crisp and vibrant prints.

3. Construction: In the building industry, paperboard is often used for insulation, temporary structures, or protective covers, showcasing its utility beyond traditional packaging.

4. Textile and Consumer Goods: The textile industry utilizes paperboard for everything from hangtags and labels to packaging for garments and accessories. Its ability to withstand handling without sacrificing design integrity makes it indispensable for fashion brands.

Conclusion

Paperboard machines are integral to producing the materials that drive modern industries forward. With their ability to efficiently produce high-quality and sustainable paperboard, these machines help manufacturers meet the growing demand for eco-friendly packaging solutions. Whether you are in packaging, printing, or any industry that requires durable and customizable material, investing in a high-performance paperboard machine is essential for maintaining production efficiency, lowering costs, and supporting sustainability efforts. As the need for eco-conscious products continues to grow, paperboard machines remain at the forefront of innovation, offering both environmental benefits and cost-effective manufacturing solutions.

Recommended products