Protective Footwear Redefined: An In-Depth Look at Safety Shoes for Workplace Safety and Comfort

Product description

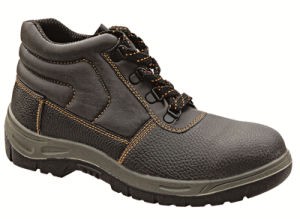

In industrial environments, construction sites, warehouses, and many other labor-intensive sectors, safety shoes are more than just footwear; they are essential protective gear that safeguard workers from potential hazards while ensuring comfort and durability. As workplaces evolve, so do the demands for footwear that not only protects but also enhances productivity. This comprehensive overview explores the core features, benefits, and diverse applications of safety shoes, giving you an all-encompassing understanding of this vital PPE (Personal Protective Equipment).

Key Features of Safety Shoes

Safety shoes are engineered with a combination of advanced materials and design principles to address various workplace risks. They typically come equipped with reinforced toe caps, often made of steel, composite, or aluminum, providing impact resistance that shields toes from falling objects or compression hazards. The midsoles often incorporate puncture-resistant plates made from steel or composite materials, preventing injuries from sharp objects on the ground. Slip-resistant outsoles, crafted from rubber or special polymer compounds, are designed to grip a variety of surfaces, reducing fall risks in wet or oily conditions.

Most safety shoes feature electrical hazard protection, insulating the wearer from static or accidental contact with live electrical circuits. Many also include water-resistant or waterproof membranes, keeping feet dry in damp environments, and are designed with ergonomic considerations to reduce fatigue during long hours of use. Breathable linings and moisture-wicking insoles enhance comfort, helping workers stay focused and comfortable even in demanding situations.

Why Choose Safety Shoes?

The primary advantage of safety shoes is their ability to mitigate workplace hazards, preventing injuries that could lead to disability, downtime, or costly medical bills. Their durability ensures that they're suitable for rigorous tasks, while modern designs also emphasize comfort, enabling prolonged wear without discomfort. They are versatile, fitting diverse industries such as construction, manufacturing, logistics, and maintenance.

Moreover, safety shoes contribute to compliance with occupational safety regulations, which often mandate the use of protective footwear in certain environments. This compliance not only reduces legal risks but also fosters a proactive safety culture within organizations.

Versatile Application Areas

Safety shoes are indispensable in environments where risks from falling objects, punctures, slips, or electrical hazards exist. Construction workers benefit from reinforced toes and slip-resistant soles, while warehouse employees working with heavy equipment rely on puncture-resistant features. Electricians and electrical engineers find insulated footwear essential for protecting against electrical shocks particularly on live circuits. Heavy machinery operators and factory workers also prefer safety shoes that combine protective features with all-day comfort to maintain efficiency and safety.

Frequently Asked Questions (Q&A)

Q1: What types of safety shoes are available for different industries?

Safety shoes vary based on industry needs. Construction-specific shoes often have steel toes and rugged soles, while electrical safety shoes may feature insulated soles and non-conductive materials. Puncture-resistant models are suitable for environments with sharp objects, and waterproof varieties are critical in wet settings.

Q2: How do I choose the right safety shoes for my job?

Assess the specific hazards of your work environment-impact risk, electrical exposure, puncture hazards, slip risks, and weather conditions. Select footwear that addresses these needs, ensuring proper fit for comfort and compliance with safety standards. Consulting with safety professionals or reviewing industry regulations can help refine your choice.

Q3: Are safety shoes comfortable to wear all day?

Modern safety shoes are designed with ergonomics and comfort in mind, incorporating cushioned insoles, breathable linings, and lightweight materials. However, proper fit is key; ill-fitting shoes can cause discomfort or foot problems, so trying different sizes or brands is advisable.

Q4: How often should safety shoes be replaced?

Depending on usage and environmental conditions, safety shoes typically last between 6 to 12 months. Signs that replacement is necessary include worn-out soles, damaged toe caps, or diminished protective features. Regular inspections are recommended to maintain safety standards.

Q5: Are safety shoes suitable for outdoor and indoor use?

Yes, safety shoes are designed to perform well in both indoor and outdoor settings. Features like rugged soles enhance outdoor traction, while waterproofing and breathability make them suitable for indoor environments. Match the specific features to your working conditions for optimal performance.

Final Thoughts

Safety shoes are a cornerstone of workplace safety, offering essential protection without sacrificing comfort or practicality. Their diverse features cater to an array of hazards across numerous industries, making them a versatile and necessary investment for safeguarding workers. Whether working on construction sites, factories, or electrical installations, choosing the right safety shoes tailored to the specific environment can significantly reduce risks and enhance safety culture. Investing in high-quality safety footwear is investing in the well-being and productivity of every worker-a decision that pays dividends in safety, compliance, and peace of mind.

Recommended products