Stepping Safely: The Essential Guide to Safety Shoes for Every Industry

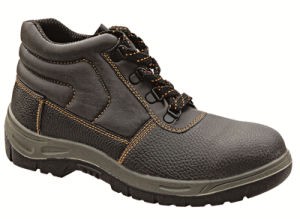

Product description

When it comes to protecting workers on the job site, safety shoes are an indispensable piece of personal protective equipment. Designed to combine durability, comfort, and protection, safety shoes serve as a critical barrier against common workplace hazards. Whether on construction sites, manufacturing plants, warehouses, or outdoor projects, the right pair of safety shoes can make a significant difference in preventing injuries and ensuring operational efficiency.

What Are Safety Shoes and Why Are They Important?

Safety shoes are specially engineered footwear that incorporates protective features such as reinforced toes, slip-resistant soles, and puncture-resistant materials. They are tailored to meet safety standards set by occupational safety authorities, ensuring maximum protection against impact, compression, punctures, slips, and electrical hazards.

These shoes are constructed from high-quality materials that withstand harsh environments and heavy use. Typical safety shoes include steel or composite toe caps that shield toes from falling objects or compressive forces. Their slip-resistant soles provide anchorage on various surfaces, reducing the risk of falls, one of the leading causes of workplace injuries. Additionally, many models feature waterproof or chemical-resistant materials to guard against environmental hazards.

Major Benefits of Safety Shoes

Investing in high-quality safety shoes offers numerous benefits beyond injury prevention. First, they improve worker confidence and comfort especially during long shifts by providing ergonomic support and reducing fatigue. Properly designed safety shoes can also enhance productivity by enabling workers to focus on their tasks without worrying about potential foot injuries.

From a safety compliance perspective, wearing the appropriate footwear ensures adherence to industry regulations, avoiding legal liabilities and potential fines. Furthermore, safety shoes contribute to a safer workplace culture by demonstrating an employer’s commitment to worker wellbeing.

Typical Applications and Use Cases

Safety shoes are versatile and applicable across a broad spectrum of industries. Construction workers rely on them to protect against falling debris, sharp objects, and uneven terrains. Manufacturing personnel need sturdy and steel-toe models to prevent foot injuries from heavy machinery or falling tools. Warehouse staff often work on slick surfaces, benefiting from slip-resistant soles. Agricultural workers face risks involving debris, mud, or unpredictable terrains, making durability and traction essential.

Additionally, safety shoes are vital in environments where electrical hazards are present, featuring non-conductive elements to prevent electrocution. The wide range of available designs ensures that workers in various sectors can find footwear that balances safety, comfort, and convenience.

Frequently Asked Questions About Safety Shoes

Q1: What features should I look for in safety shoes?

Look for safety shoes with impact-resistant toe caps, slip-resistant soles, puncture-resistant insoles, and appropriate material durability. Also consider comfort features like cushioned insoles and ergonomic support for extended wear.

Q2: Are safety shoes suitable for outdoor use?

Absolutely! Many safety shoes are designed specifically for outdoor environments, incorporating waterproofing, rugged outsoles, and weather-resistant materials suitable for rough terrain and varying weather conditions.

Q3: How do I ensure my safety shoes fit properly?

Proper fit is critical for safety and comfort. Measure your feet regularly and select shoes that provide enough space in the toe box, good arch support, and snug but not tight fit. Trying shoes on in the late afternoon or evening, when feet are at their widest, can help ensure better sizing.

Q4: Can safety shoes be worn all day?

Yes, modern safety shoes are engineered for all-day comfort, but choosing the right pair and ensuring proper fit are essential. Look for models with cushioned insoles and breathable materials to reduce fatigue and discomfort.

Q5: How often should safety shoes be replaced?

It depends on usage, but generally every 6 to 12 months for regular wear. Check for signs of wear such as cracks, thinning soles, or loss of protective features. Worn-out footwear compromises safety and should be replaced promptly.

Final Thoughts: Confidence in Every Step

Whichever industry you work in, investing in the right safety shoes is a decision that prioritizes your security and productivity. Modern safety footwear combines rugged durability with ergonomic comfort, broadening their role from mere protective gear to a vital element of everyday workwear. By understanding your specific needs and selecting appropriate features, you can create a safer and more efficient work environment while taking each step forward confidently.

Recommended products