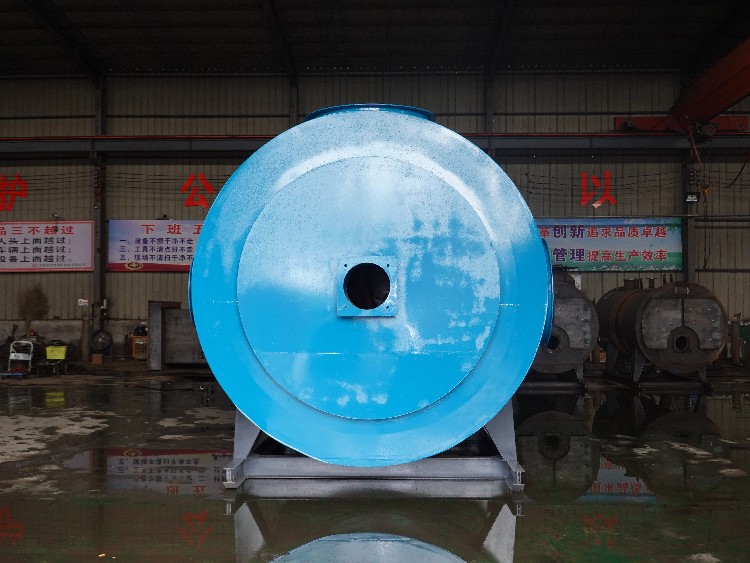

WRF Series Horizontal Multi-Fuel Hot Air Heater 1.05-1.4MW 60-300C Pure Air Output

Product description

Product Overview

Our WRF Series Horizontal Multi-Fuel Hot Air Heater represents advanced heating technology for industrial processes requiring clean, high-temperature air. With an output range of 1.05-1.4MW and temperature capabilities from 60-300°C, this system delivers pure air output without combustion contaminants, making it ideal for sensitive industrial applications. The unit's multi-fuel capability and horizontal design provide exceptional flexibility and reliability for continuous operation.

Key Advantages:

- Pure Air Output: Provides 100% clean hot air through indirect heating technology, ensuring no combustion gases contact the process air, perfect for food processing and pharmaceutical applications

- Multi-Fuel Flexibility: Compatible with natural gas, light diesel, heavy oil, and city gas, offering adaptability to local fuel availability and cost considerations

- Wide Temperature Range: Delivers stable output temperatures from 60°C to 300°C with precise control, suitable for various industrial processes

- High Thermal Efficiency: Achieves 86% thermal efficiency through optimized heat exchange design, reducing fuel consumption and operating costs

- Horizontal Compact Design: Space-saving configuration with easy access for maintenance and service

Technical Specifications

| Parameter | WRF-60 | WRF-80 | WRF-100 | WRF-120 | Unit |

|---|---|---|---|---|---|

| Rated Power | 0.7 | 1.05 | 1.2 | 1.4 | MW |

| Temperature Range | 60-300 | 60-300 | 60-300 | 60-300 | °C |

| Thermal Efficiency | 86 | 86 | 86 | 86 | % |

| Natural Gas Consumption | 93 | 124 | 155 | 186 | m³/h |

| Light Diesel Consumption | 76 | 102 | 127 | 153 | kg/h |

| Heavy Oil Consumption | 78 | 104 | 130 | 156 | kg/h |

| Air Flow Capacity | 10,000-15,000 | 15,000-20,000 | 20,000-25,000 | 25,000-30,000 | m³/h |

| Power Supply | 380V/50Hz/3Phase | 380V/50Hz/3Phase | 380V/50Hz/3Phase | 380V/50Hz/3Phase | - |

| Shipping Weight | 3.7 | 4.5 | 5.5 | 6.6 | Ton |

Applications

This hot air heater is ideal for:

- Food and beverage processing drying systems

- Pharmaceutical and chemical product drying

- Spray booth and painting room heating

- Industrial building space heating

- Agricultural product drying and processing

- Textile and printing drying processes

Why Choose Our Hot Air Heater?

- Clean Process Air: Indirect heating design ensures absolutely clean air output, free from combustion contaminants

- Robust Construction: Heavy-duty steel construction with high-temperature corrosion resistance

- Precise Temperature Control: ±2°C temperature stability for critical process requirements

- Low Maintenance: Easy access design and simple maintenance procedures reduce downtime

- Energy Efficient: Recirculation capability and heat recovery options available

Packaging & Shipping

- Main Unit: Weather-proof packaging with steel frame protection

- Heat Exchanger: Special anti-corrosion treatment and separate protection

- Control System: IP65 protection grade, wooden case packaging

- Export Standard: All packages meet international shipping requirements

FAQ

- Q: What makes the air output "pure"?A: The indirect heating design separates the combustion chamber from the process air, ensuring no combustion gases mix with the output air.

- Q: Can I switch between different fuels?A: Yes, but it requires burner adjustment or replacement. Please specify your primary fuel requirement when ordering.

- Q: What is the maximum operating temperature?A: The system can consistently maintain output temperatures up to 300°C with stable performance.

- Q: Is special installation required?A: The horizontal design simplifies installation, but we recommend professional installation for optimal performance and provide detailed installation guidelines.

Contact us for more technical details and application-specific solutions!

Recommended products