Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Product description

In the world of high-volume wood processing, achieving maximum output without sacrificing precision is the ultimate goal. Multi-blade rip saws stand at the forefront of this mission, offering a revolutionary approach to ripping lumber into multiple identical strips in a single, powerful pass. These machines are engineered for operations where time, material yield, and consistent dimensional accuracy are critical to profitability. By utilizing a series of blades mounted on a single arbor, they transform raw lumber into finished strips ready for further processing with breathtaking speed and uniformity. This guide explores the inner workings, benefits, and practical applications of multi-blade rip saws, providing a clear understanding of how they can become the cornerstone of a modern, efficient millwork or manufacturing facility.

Core Features of Multi-Blade Rip Saws

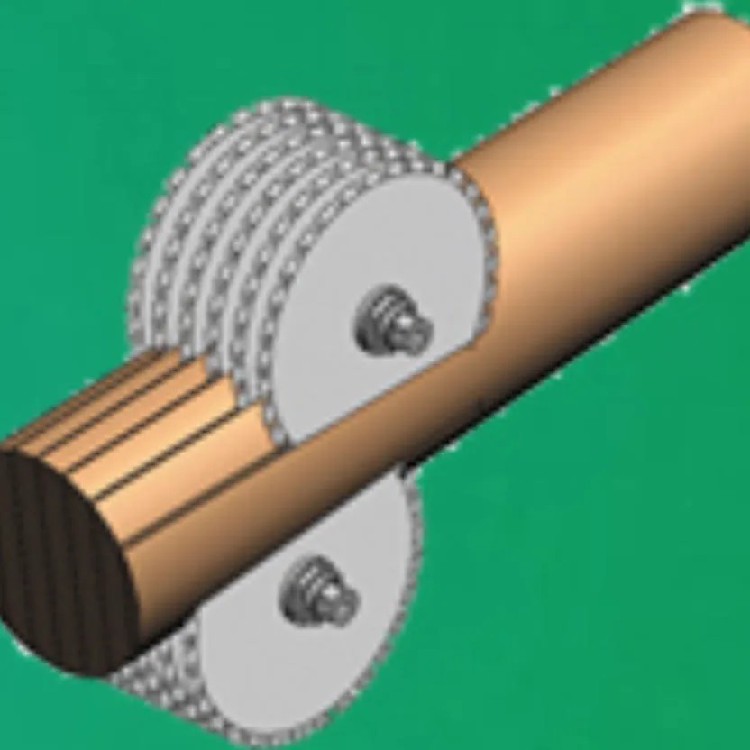

The defining characteristic of a multi-blade rip saw is its ability to make multiple parallel cuts simultaneously. This is achieved through a robust arbor that holds a set of precision-ground blades, which can be spaced according to the desired output width. The arbor is driven by a high-power motor designed to maintain constant speed under heavy load, ensuring clean cuts through even the densest hardwoods. Modern versions often incorporate sophisticated infeed and outfeed systems, including powered rollers and precision guides, to smoothly transport the workpiece and minimize vibration. For enhanced flexibility, many systems feature easy-to-adjust blade positioning mechanisms, allowing for quick changeovers between different cutting patterns. Dust collection ports are integral to the design, maintaining a clean work environment and protecting the machinery's moving parts.

Significant Advantages for High-Volume Production

The advantages of integrating a multi-blade rip saw into a production line are substantial and directly impact the bottom line. The most significant benefit is the dramatic increase in throughput. By producing numerous strips from a single board in one operation, these machines exponentially increase output compared to single-blade alternatives. This efficiency directly translates to higher production capacity and the ability to fulfill large orders on tight schedules. Secondly, the precision engineered setup ensures every strip is dimensionally identical, eliminating variation and reducing waste from inaccuracies. This optimization of material usage maximizes yield from each raw board, leading to considerable cost savings on materials over time. Furthermore, while the initial setup requires expertise, the operation itself can often be managed by a single operator, optimizing labor allocation and reducing the potential for operator-dependent errors.

Primary Applications and Use Cases

Multi-blade rip saws are indispensable in environments that require high-volume, consistent output of dimensional lumber. They are the workhorses of pallet manufacturing, where they rapidly produce deck boards and stringers of uniform size. In the furniture industry, they are used to prepare stock for components like table slats, chair spindles, and frame parts. Door and window manufacturers rely on them to produce countless stiles and rails with identical profiles. Additionally, they are essential in the production of flooring strips, shelving components, and any application where large quantities of precise, parallel-sided wood strips are needed. Their design makes them ideal for processing both softwoods and hardwoods, catering to a wide range of product requirements.

Frequently Asked Questions About Multi-Blade Rip Saws

Q: How is the blade spacing adjusted for different cut widths?

A: Blade spacing is typically adjusted using spacers or collars that fit onto the arbor between the blades. Advanced systems may feature hydraulic or electronic positioning for faster, more precise adjustments, minimizing downtime between jobs.

Q: What type of maintenance do these machines require?

A: Regular maintenance includes checking blade sharpness and integrity, ensuring the arbor is properly aligned and tensioned, lubricating moving parts, and keeping the dust collection system clear. Consistent maintenance is key to preserving cut quality and machine longevity.

Q: Can a multi-blade rip saw handle curved or irregular lumber?

A: These saws are designed for ripping straight, flat-edged lumber. Curved or irregular stock typically requires initial processing through a straight-line edger before being fed into the multi-blade saw to ensure safety and cut accuracy.

Q: How does this machine improve material yield?

A: By making all cuts simultaneously and with precise spacing, the machine minimizes the kerf (width of the cut) waste between each board. This optimized cutting pattern ensures the maximum number of usable strips is obtained from each piece of raw material.

Q: Are they suitable for small shops?

A: Due to their size, power requirements, and focus on high-volume production, multi-blade rip saws are generally most suitable for medium to large-scale operations. Smaller shops might find their output needs are met by a single-blade saw with optimizing capabilities.

Q: What safety features are common?

A: Standard safety features include emergency stop buttons, magnetic brakes that stop the arbor quickly, fully enclosed cutting chambers, and interlocked guards that prevent access to the blades while they are in motion.

Investing in Streamlined Production

The multi-blade rip saw is more than just a cutting tool; it is a strategic investment in industrial-grade productivity and material optimization. For businesses focused on volume production of dimensional lumber, its ability to deliver unmatched speed and consistency is unparalleled. By understanding its robust features and operational advantages, manufacturers can make an informed decision about integrating this powerful technology into their workflow, ultimately driving growth and enhancing competitive advantage in the market.

Recommended products