How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

Product description

In today's competitive wood processing industry, achieving maximum productivity while maintaining precision is no longer an option—it's a necessity. Multi-blade sawing systems represent the pinnacle of cutting technology, engineered to transform raw timber into multiple uniform boards in a single, seamless operation. These industrial powerhouses are designed for manufacturers who refuse to compromise on output quality, operational efficiency, or material utilization. By employing a sophisticated arrangement of precisely spaced blades on a heavy-duty arbor, these machines deliver consistent, parallel cuts that would take conventional saws multiple passes to accomplish. This comprehensive examination explores how multi-blade technology can become the backbone of your wood processing operation, driving profitability through engineered excellence.

Engineering Excellence: Core Technical Specifications

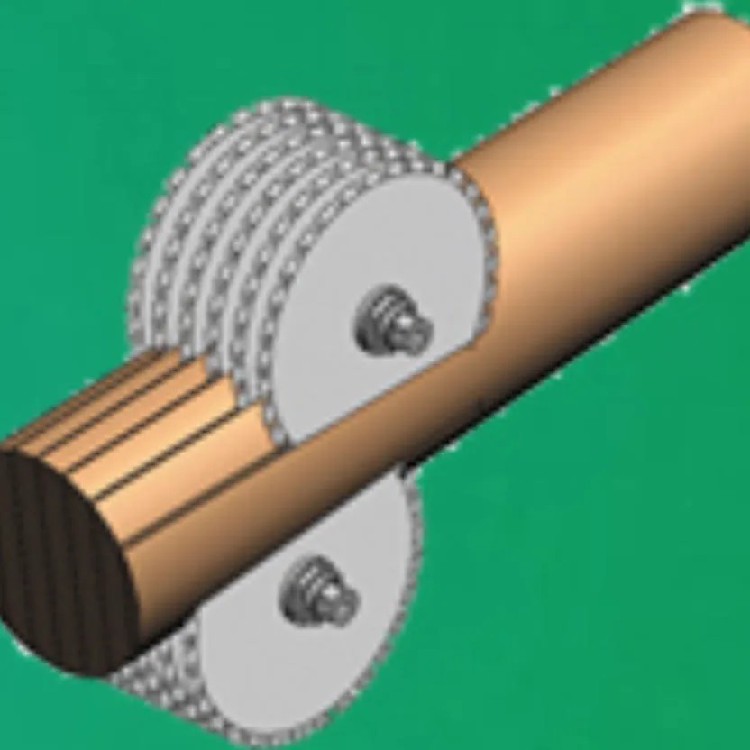

The fundamental principle behind multi-blade sawing systems lies in their synchronized cutting mechanism. A high-capacity motor drives a reinforced steel arbor that houses multiple cutting blades, each positioned with exacting precision using specialized spacers. This arrangement allows for simultaneous processing of entire batches of lumber, significantly reducing processing time. Modern iterations feature advanced vibration dampening systems that ensure blade stability during operation, resulting in exceptionally clean cuts with minimal tear-out. The integration of automated feed systems with adjustable speed controls allows operators to maintain optimal cutting rates for various wood densities, from softwoods like pine to dense hardwoods such as oak. Additionally, these systems incorporate sophisticated dust extraction technology that not only maintains workplace cleanliness but also enhances visibility and reduces wear on mechanical components.

Operational Advantages for Modern Manufacturing Facilities

The implementation of multi-blade sawing technology delivers transformative benefits that directly impact operational metrics. The most immediately noticeable advantage is the exponential increase in production capacity. By processing multiple boards in a single operation, these systems can achieve output volumes that would require multiple conventional saws and operators. This production efficiency translates directly into reduced labor costs and faster order fulfillment capabilities. The precision engineering of these systems ensures dimensional consistency across all produced pieces, virtually eliminating variation and reducing material waste to absolute minimums. This precision directly improves material yield, maximizing the value extracted from each raw timber unit. Furthermore, the reduced handling requirements decrease the risk of workpiece damage and enhance overall workplace safety by minimizing operator interaction with cutting components.

Industrial Applications and Implementation Scenarios

Multi-blade sawing systems find their ideal application in high-volume production environments where consistent dimensional output is paramount. These machines serve as the fundamental processing equipment in pallet manufacturing facilities, where they efficiently produce deck boards and stringers in massive quantities. The furniture manufacturing industry relies on these systems for producing identical components for chair frames, table supports, and cabinet elements. Door and window manufacturers utilize multi-blade technology for creating stiles, rails, and other structural components that require exact dimensional matching. Additionally, these systems are indispensable in flooring production, shelving manufacturing, and any application requiring large volumes of precisely dimensioned wood strips. Their robust construction and configurable nature make them suitable for both softwood and hardwood processing operations across various industry segments.

Expert Insights: Frequently Asked Questions

Q: How frequently do the blades require maintenance or replacement?

A: Blade maintenance intervals depend on material processed and production volume. Generally, blades require sharpening after every 100-150 hours of operation for hardwoods, or 200-250 hours for softwoods. Complete replacement is typically needed after 5-7 sharpening cycles.

Q: What safety systems are integrated into these machines?

A: Modern systems feature comprehensive safety packages including emergency stop systems, blade brakes, interlocked guarding mechanisms, infrared safety curtains, and automatic shutdown systems that activate upon detecting material feeding abnormalities or mechanical issues.

Q: How does blade configuration affect production flexibility?

A: Blade spacing can be reconfigured using precision spacers, allowing manufacturers to quickly adapt to different product specifications. Some advanced systems feature computerized spacing adjustment that can be programmed for different production runs.

Q: What power requirements are typical for these systems?

A: Industrial multi-blade systems typically require three-phase electrical power, with motor configurations ranging from 15HP for smaller units to 50HP+ for heavy-duty industrial applications, depending on blade quantity and intended material density.

Q: Can these systems process recycled or irregular timber?

A: While designed for milled timber, some systems can process recycled materials when equipped with specialized feeding systems and reinforced blade configurations. However, optimal performance is achieved with properly prepared raw material.

Q: How do these systems integrate with existing production lines?

A: Most manufacturers design their systems with modular integration capabilities, allowing connection to existing material handling systems, conveyor networks, and digital production management systems through standardized interfaces.

Recommended products