The King of Durability and Cost-effectiveness: PU Synthetic Leather

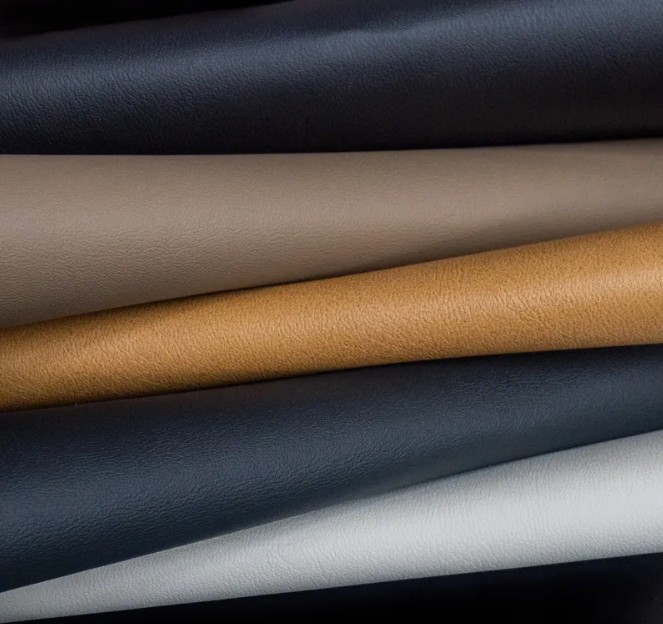

Product description

In an era where innovation meets practicality, a versatile material has steadily transformed countless industries. PU synthetic leather stands as a testament to advanced material science, offering a compelling blend of aesthetic appeal, performance, and conscientious manufacturing. Far from being a simple imitation, today's PU leather is a high-tech fabric engineered for modern life. It bridges the gap between the desirable look and feel of natural leather and the demanding requirements of contemporary applications. This article delves into the intricacies of PU synthetic leather, exploring its composition, inherent advantages, and the vast landscape of its use, providing a clear understanding of why it has become a material of choice for designers and manufacturers worldwide.

Deconstructing the Material: What Exactly is PU Synthetic Leather?

Polyurethane (PU) synthetic leather is a sophisticated multilayer material. Its creation begins with a base substrate, typically a polyester or cotton fabric, which provides foundational strength and tear resistance. This base is then coated with a flexible and durable film of polyurethane. This polymer layer is the heart of the material, engineered to mimic the grain and texture of natural leather. Through advanced manufacturing techniques, embossed patterns are applied to the surface, creating convincing replicates of everything from full-grain leather to exotic animal skins. The result is not a cheap substitute, but a purpose-built material with a consistent quality and performance profile that can be precisely tailored to specific needs.

Inherent Properties: The Core Features of PU Leather

The performance of PU synthetic leather is defined by a suite of key characteristics that make it exceptionally reliable. One of its most lauded properties is its outstanding abrasion resistance. The polyurethane surface is inherently tough, allowing it to withstand significant wear and tear from repeated use, making it ideal for high-traffic applications. This durability is coupled with a remarkable flexibility and soft hand-feel. Unlike some materials that stiffen in cold conditions, PU leather remains pliable across a wide temperature range, ensuring comfort and functionality.

Furthermore, PU synthetic leather exhibits a high degree of water and moisture resistance. The non-porous polyurethane layer acts as an effective barrier, preventing liquid absorption and making the material easy to clean and maintain. This resistance also guards against mildew growth, a crucial factor for applications in humid environments. Finally, the material boasts excellent color and design consistency. Because it is manufactured in controlled rolls, it does not suffer from the natural imperfections and color variations of hide-based leather, granting designers unparalleled creative freedom.

Tangible Advantages: Why Choose PU Synthetic Leather?

The features of PU leather translate into significant benefits for both manufacturers and end-users. Perhaps the most prominent advantage is its exceptional cost-effectiveness. It provides the luxurious appearance of leather without the high price point associated with raising, tanning, and processing animal hides, enabling more accessible product pricing. From an ethical and environmental standpoint, PU leather offers a compelling vegan alternative. Its production does not involve animal products, aligning with growing consumer preferences for cruelty-free materials.

The material's uniformity and ease of production are major logistical benefits. It can be produced in wide, continuous rolls of consistent thickness, color, and texture, which simplifies the cutting and manufacturing process, reduces waste, and streamlines supply chains. For the consumer, the advantage of effortless maintenance is a key selling point. Spills and stains can typically be wiped away with a damp cloth, and the material does not require the specialized conditioners that natural leather often does, ensuring it looks its best for longer with minimal effort.

A World of Applications: Where You'll Find PU Leather

The versatility of PU synthetic leather sees it deployed across a stunningly diverse range of sectors. In the fashion and accessories industry, it is a fundamental material for crafting stylish footwear, durable handbags, modern wallets, and chic belts. The furniture and interior design world heavily relies on it for producing upholstery for sofas, armchairs, and office furniture, offering a perfect balance of comfort, style, and easy cleaning for both homes and commercial spaces.

The automotive industry is another major adopter, where PU leather is used for car seats, steering wheel covers, and interior door panel trim, meeting rigorous standards for durability, UV resistance, and passenger comfort. Furthermore, its use in sports and leisure goods, such as equipment covers, balls, and gym gear, highlights its toughness and resilience. You will also find it in personal electronics cases and a myriad of specialty items, proving its adaptability is nearly limitless.

Answering Your Questions: A PU Leather Q&A

1. How does PU leather differ from genuine leather in terms of breathability?

Genuine leather is a natural, porous material that allows for some air passage. PU leather, with its solid polymer coating, is generally less breathable. However, advanced manufacturing techniques can create perforated or textured versions that improve air circulation for specific applications where this is a concern.

2. What is the typical lifespan of a product made from high-quality PU leather?

The lifespan is highly dependent on the quality of the base fabric and polyurethane coating, as well as the conditions of use. A well-made product from high-grade PU leather can last for many years with proper care, offering excellent resistance to cracking and peeling under normal circumstances.

3. Are there specific cleaning agents to avoid when maintaining PU leather?

It is generally advisable to avoid harsh chemicals such as strong solvents, bleach, or abrasive cleaners. These can degrade the polyurethane surface and damage the color. For routine cleaning, a soft cloth dampened with a mild soap solution or a cleaner specifically formulated for synthetic leather is perfectly adequate.

4. Can PU leather be considered an environmentally friendly material?

The environmental impact is complex. While its production avoids the livestock industry's ecological footprint, it is a petroleum-derived product. The industry is increasingly focusing on more sustainable practices, including the use of recycled polyester for the base fabric and the development of bio-based polyurethanes, enhancing its eco-friendly credentials.

5. How can consumers identify high-quality PU leather from lower-grade alternatives?

High-quality PU leather will have a consistent, supple feel without a strong chemical odor. The backing fabric should feel substantial, not thin or flimsy. The grain pattern should look detailed and natural, and the material should spring back smoothly when gently folded without leaving a permanent crease. A reputable supplier will often provide specifications regarding abrasion resistance and colorfastness.

Recommended products