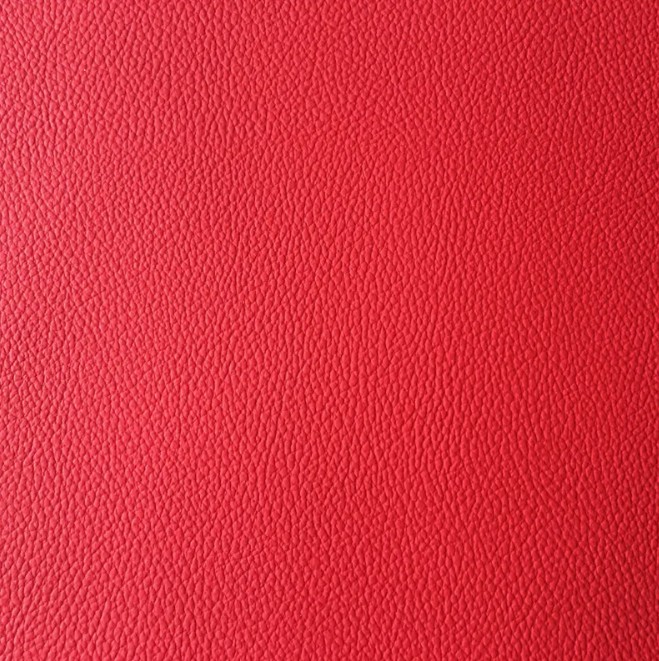

Wholesale Artificial Leather Material Pvc Synthetic Leather Fabric

Product description

In the landscape of modern materials, few options offer the balance of performance, economy, and adaptability found in PVC synthetic leather. As a pioneering material with a long history of innovation, PVC leather has evolved into a sophisticated product that meets the rigorous demands of diverse industries. It stands as a robust and intelligent choice for applications where consistency, durability, and value are paramount. This material is not merely an alternative but a primary selection for countless designers, manufacturers, and consumers around the globe. This comprehensive guide explores the fundamental nature of PVC leather, its defining characteristics, the concrete benefits it delivers, and the vast array of its practical uses.

Understanding the Foundation: What is PVC Synthetic Leather?

Polyvinyl Chloride (PVC) synthetic leather is a composite material engineered for resilience and uniformity. Its construction typically involves a fabric backing, commonly made from polyester or cotton, which serves as a strong and flexible base layer. This substrate is then coated with a plasticized PVC compound. Through a process that includes heat, pressure, and embossing, this layer is transformed into a durable surface that can replicate the grain and texture of genuine leather or showcase unique, modern designs. The result is a uniform sheet material that delivers predictable performance, batch after batch, making it a reliable component for mass production and specialized projects alike.

Defining Characteristics: The Inherent Properties of PVC Leather

The widespread adoption of PVC synthetic leather is rooted in a set of core physical properties that make it exceptionally reliable. Foremost among these is its exceptional toughness and abrasion resistance. The PVC surface is highly resistant to scuffs, scratches, and general wear, ensuring that products maintain their new appearance even after extensive use. This durability is matched by its impressive water and moisture resistance. Unlike porous materials, PVC leather acts as an effective barrier, preventing liquid absorption. This inherent quality makes it easy to clean and highly resistant to mildew and staining, ideal for both indoor and outdoor environments.

Furthermore, PVC leather exhibits remarkable chemical resilience. It can withstand exposure to a range of common chemicals, including acids and alkalis, without deteriorating. This property is crucial for applications in healthcare, cleaning, and industrial settings. The material is also inherently flame-retardant, adding a critical layer of safety for use in public spaces, transportation, and electronics. Finally, it offers outstanding color consistency and printability. Manufacturers can produce it in a virtually limitless spectrum of vibrant colors and intricate patterns, providing unparalleled creative freedom without the natural variations found in animal hides.

Practical Advantages: The Compelling Reasons to Choose PVC Leather

The technical features of PVC leather translate into significant real-world advantages for businesses and end-users. One of the most powerful benefits is its outstanding cost-effectiveness. It provides a consistent, high-performance material at a fraction of the cost of genuine leather, enabling more accessible product pricing and reducing material costs for manufacturers. From a performance perspective, its low maintenance requirement is a major selling point. Spills and dirt can be wiped away with a damp cloth, and it does not require the conditioning or specialized treatments that natural leather often demands.

Another key advantage lies in its structural integrity and versatility. PVC leather is less susceptible to drying out and cracking over time compared to some alternatives when formulated correctly. It can be manufactured in wide, continuous rolls, which streamlines the cutting process for manufacturers, minimizes waste, and ensures a consistent supply. This combination of practical benefits makes it an economically smart and logistically friendly choice for large-scale production runs.

A Spectrum of Applications: Where PVC Leather Excels

The utility of PVC synthetic leather spans a remarkably broad range of sectors, a testament to its adaptable nature. In interior design and furniture, it is a staple for upholstering sofas, chairs, and headboards in both residential and commercial settings, offering a perfect blend of aesthetic appeal and easy upkeep. The automotive industry relies on it for durable seat covers, door panel trims, and dashboards, where it must meet strict standards for wear and cleaning.

You will also find PVC leather in the fashion and goods sector, used for producing sturdy footwear, wallets, belts, and bags. Its protective qualities make it ideal for cases and coverings for musical instruments, sports equipment, and tools. In public and institutional environments, such as hospitals, schools, and public transportation, its hygienic, easy-to-clean, and flame-retardant properties are indispensable for seating and protective barriers.

Clarifying Common Queries: A PVC Leather Q&A

1. How does PVC leather differ from PU leather?

The primary difference lies in the polymer coating. PVC uses a polyvinyl chloride layer, which is typically more rigid and requires plasticizers for flexibility, resulting in a very robust and water-resistant material. PU (Polyurethane) leather uses a softer, more flexible polymer coating that often gives it a feel closer to genuine leather and better breathability, though it can be less water-resistant than PVC.

2. Is PVC leather considered a durable material?

Yes, high-quality PVC leather is renowned for its exceptional durability. Its resistance to abrasion, moisture, and tearing allows it to withstand heavy use over long periods, making it a preferred material for high-traffic applications like commercial furniture and automotive interiors.

3. What is the best way to clean and maintain products made from PVC leather?

Routine cleaning is straightforward. Simply wipe the surface with a soft cloth dampened with a mild soap solution or a cleaner designed for synthetic materials. It is important to avoid harsh solvents, abrasive pads, or excessive heat, as these could damage the surface finish over time.

4. Has the modern production of PVC leather addressed historical environmental concerns?

The industry has made significant strides. Modern manufacturing increasingly focuses on reducing environmental impact through methods like phthalate-free plasticizers, recycling production waste, and improving energy efficiency. Furthermore, the long lifespan of PVC leather products can contribute to sustainability by reducing the frequency of replacement.

5. Can PVC leather be produced in textures and finishes other than a leather look?

Absolutely. One of the greatest strengths of PVC leather is its design versatility. While it perfectly mimics various leather grains, it can also be embossed with an infinite variety of custom patterns, geometric designs, glossy or matte finishes, and even printed with digital graphics for truly unique applications.

Recommended products