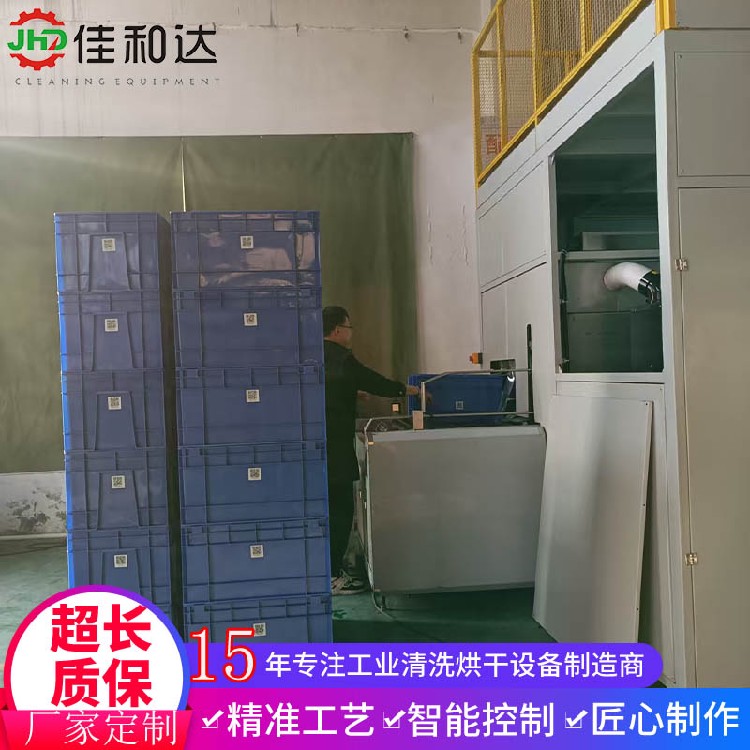

Pass-through multi-angle spray tray cleaning machine

Product description

The passing tray cleaning machine is a modern industrial cleaning equipment that combines efficiency, energy saving and environmental protection. It is designed for rapid, high-volume cleaning logistics turnover pallets (plastic pallets, wood pallets and metal pallets), and achieves a fully automated cleaning process from "dirty pallet inlet" to "clean pallet export" through a continuous operation mode of "high pressure spraying + automatic delivery." This equipment is the ideal solution for food and beverage, chemical and pharmaceutical, cold chain logistics, warehousing centers and manufacturing to improve hygiene standards, reduce labor costs and achieve green production.

Core product advantages

1. Extreme cleanliness, one step at a time

· Five-stage (or multiple-stage adjustable) high-pressure sprinkler system: built-in pre-flushing, main cleaning (many angles), washing, disinfecting (optional), and water washing. No dead corners cover the surface and cracks of the tray, and strongly remove oil, residue, labels, microorganisms and other persistent stains.

2. Excessive efficiency and labor savings

· Continuous through operation: The tray does not need to stop, passes through the cleaning tunnel at a uniform speed on the transmission chain, and the cleaning capacity can reach XX-XX / hour (depending on the model), which is several tens of times more efficient than manual cleaning.

· Completely automatic operation: One person can complete the whole process of loading, cleaning and lowering materials, completely liberating labor, and eliminating the uncontrollable nature of human cleaning.

3. Energy efficient and environmentally friendly, and cost controllable

· Smart water recycling system: Equipped with multi-layer filtering devices (such as scraping, hair filtering, sediment collection), more than 85% of cleaning water can be recycled, significantly reducing water consumption and sewerage costs.

· Heat recovery (optional): The drying section (optional) can integrate a heat recovery module to reduce energy waste.

· Low quantity of agents: The automatic dispensing system accurately controls the amount of cleaning / disinfectant used to avoid waste.

4. Strong, durable and adaptable

· Heavy industrial structure: the main body is made of SUS304 stainless steel, corrosion resistance, easy to clean, long life.

· Flexible design: Delivery width and height can be customized, and compatible with plastic trays and wooden trays of various specifications such as Euro Standard, Sichuan ®, Titian ®, and Nine Feet.

· Intelligent control system: PLC + touch screen control, can flexibly set cleaning time, temperature, speed and other parameters, the state in service at a glance, automatic failure alarm.

5. Expanded functionality, multi-use

· Modular design: It can be equipped with "powerful hot air drying module," "disinfectant spray module," "automatic waste residue collection device" and so on, to meet the special needs of different industries (such as food, medicine).

Principles and Processes

1. Preposition: Laundry trays are placed manually or through a tumbler line / lift on the equipment entrance conveyor chain.

2. Conveying: The conveying chain is driven by speed regulation by frequency variation motor.

3. High-pressure cleaning: Multiple rows of stainless steel nozzles in the tunnel, up and down, and left and right, spray high-pressure water on the tray from different angles to complete the core cleaning steps of pre-cleaning, main cleaning, and bleaching.

4. (Optional) Disinfection / drying: Depending on configuration, then enter a disinfection spray area and finally enter an efficient hot air drying area to remove surface moisture and achieve washing and drying immediately.

5. Preparation: Clean and dry pallets are delivered from the export end and can be loaded directly or put into the next stage of use.

Standard technical parameters (examples, which can be customized to your device)

Item Parameter Dxplaination

Device Model TTPW-1500 (Example)

Plastic, wood, metal pallets (maximum size can be customized, such as L1200-1500mm x W1000-1200mm)

Cleaning capacity 100-400 pcs per hour (depending on the degree of dirt on the tray and the cleaning process)

Working temperature Room temperature ~ 75 ° C (adjustable, heating mode: steam / electric heating)

Total power approx. XXkW (depending on configuration)

Water pressure ≥ 0.3

Water consumption is recycled with very low replenishment (e.g. 0.5-1 m3 / h)

Main material SUS304 stainless steel

Control system PLC + color touch screen (Chinese-English interface)

Dimensions approx. Lxxxxx Wxxxxx Hxxxxmm (customized according to the number of stations)

Applicable industry and scenario

· Food and beverage industry: cleaning trays with food residue, grease, syrup, in line with HACCP / GMP hygiene standards.

· Chemical and pharmaceutical industries: Removing raw material dust and chemical residues to prevent cross contamination.

· Cold chain logistics and warehousing: Clean trays used in refrigerated and frozen environments to remove frost, blood and odors.

· Manufacturing and automotive parts: Cleaning rotating trays with organic oil and metal debris.

· Leasing and third-party logistics companies: clean recycled shared pallets on a large scale and in a standardized manner to improve pallet turnover and value.

We offer not only equipment, but solutions.

We support non-standard customization to design the most appropriate equipment scheme and installation and commissioning services for your plant layout, pallet type, cleanliness requirements and productivity goals.

Consult today for exclusive quotes and offers!

Recommended products