The Wood Peeler: Unveiling the Core of Veneer Production

Product description

A wood peeler (or veneer lathe) is a sophisticated industrial machine that transforms logs into continuous, ultra-thin sheets of wood known as veneer. This process, called rotary peeling, is fundamental to producing plywood, laminated veneer lumber (LVL), and decorative veneers. Unlike sawing, peeling maximizes yield from each log, making it a highly efficient and economical method for utilizing valuable timber resources.

Machine Mechanics: How a Wood Peeler Works

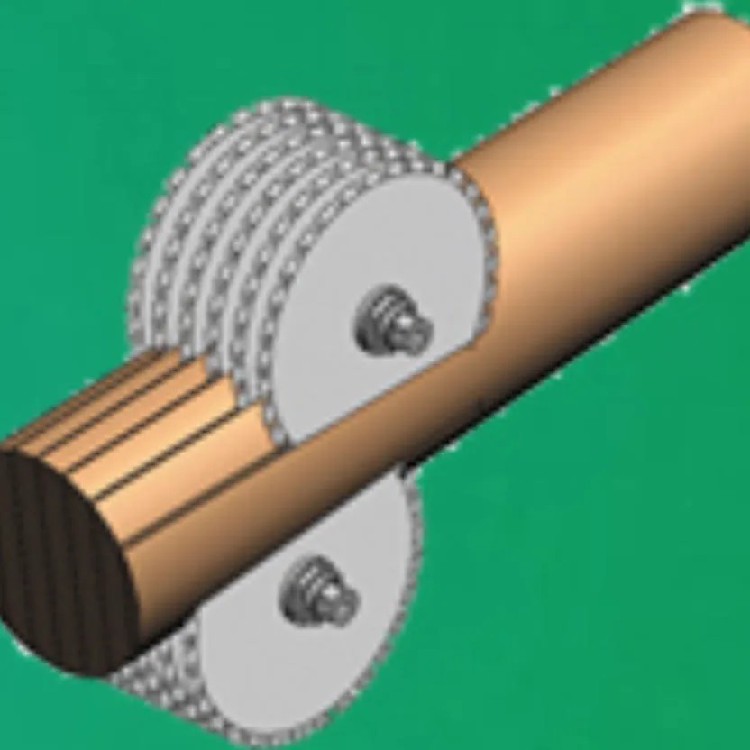

- Core Components:Lathe Bed & Drive: Heavy-duty frame housing powerful spindles that grip and rotate the log at high speed.Chucks/Spindles: Hydraulic or mechanical clamps that secure the log at both ends and drive its rotation.Pebble (Pressure Bar): A critical component positioned just above and ahead of the peeling knife. It compresses the wood fibers ahead of the cut, minimizing checking (splitting) on the veneer's loose side and ensuring a smoother cut.Peeling Knife: A long, extremely sharp blade spanning the machine's width. It contacts the rotating log, shaving off a continuous sheet of veneer at a precise, predetermined thickness.Knife & Pebble Adjustment System: Precision hydraulics or CNC controls that dynamically adjust the knife and pebble position as the log diameter decreases, maintaining optimal pressure and cut quality.Veneer Conveyor/Clips: Transports the fragile, continuous veneer sheet away from the lathe for clipping, drying, and handling.

- The Peeling Process:A pre-conditioned log (often steamed or soaked for plasticity) is loaded and centered between the chucks.The chucks clamp the log and rotate it at high speed.The sharp peeling knife, guided by the pressure bar, engages the rotating log.A continuous ribbon of veneer, as thin as 0.2mm or up to several millimeters thick, is sliced off the log.The knife/pebble assembly advances inward incrementally with each rotation as the log diameter decreases.The veneer ribbon is conveyed away, typically clipped into sheets by an automated system.Peeling continues until the core (typically 50-90mm diameter) is too small for quality veneer.

- Key Types:Staylog Lathes: The log rotates, but the knife carriage remains stationary. Common for smaller mills or specialty veneers.Planetary Lathes: The log remains stationary while multiple knives rotate around it. Rare, used for very large diameters.CNC/Variable Geometry Lathes: Modern machines using computer control to optimize knife and pebble angles dynamically for different wood species, log conditions, and veneer thicknesses, maximizing quality and yield.

Machine Applications: Where Peeled Veneer Shines

- Plywood Core & Cross Bands: The vast majority of the inner plies (layers) of structural and industrial plywood are rotary-peeled veneer.

- Laminated Veneer Lumber (LVL): Continuous veneer sheets are layered, glued parallel to the grain, and pressed into strong, dimensionally stable structural beams.

- Container Flooring: Thicker peeled veneer is a key component in the laminations for heavy-duty shipping container floors.

- Decorative Veneers (Lower Grades): While the highest grades often use slicing, rotary peeling produces attractive, more rustic patterns (especially from species like Birch, Maple, Lauan, Okoume) used extensively in furniture cores, cabinet backs/sides, and interior paneling.

- Molded Products: Thin, flexible veneer is ideal for laminating over curved forms (e.g., chair backs, door panels).

- Packaging & Pallets: Lower-grade veneer finds use in specialized packaging and pallet components.

5 Common Questions & Answers About Wood Peelers

- Q: What types of wood are best suited for rotary peeling?A: Straight-grained, relatively defect-free hardwoods and softwoods are ideal. Common species include Birch, Maple, Poplar, Pine, Spruce, Fir, Lauan, Okoume, and Eucalyptus. Dense, brittle woods or those with interlocked grain (like some tropical hardwoods) are harder to peel well without significant checking or roughness. Conditioning (steaming/soaking) is crucial for many species to plasticize the wood.

- Q: Why is the pressure bar (pebble) so important?A: The pebble is arguably more critical than the knife itself for quality veneer. By compressing the wood fibers just ahead of the knife cut, it:Reduces Loose-Side Checking: Minimizes the tiny splits that form on the inner surface of the veneer as it bends over the knife.Improves Surface Smoothness: Produces a tighter, smoother cut on the tight side (outer surface).Controls Veneer Thickness: Helps maintain consistent thickness across the sheet.Reduces Knife Wear: Lessens friction and impact on the knife edge.

- Q: What factors affect the quality and yield of peeled veneer?A: Key factors include:Log Quality: Straightness, diameter, absence of knots/defects, heart position.Conditioning: Adequacy and uniformity of steaming/soaking.Lathe Setup & Maintenance: Knife sharpness, knife angle, pebble position/geometry, pebble pressure, chuck alignment, machine vibration.Operator Skill/CNC Programming: Optimal settings for species, log condition, and desired thickness.Core Size: The smaller the core left, the higher the yield, but peeling very small cores can compromise quality.

- Q: How does a wood peeler differ from a veneer slicer?A:Peeler (Rotary Lathe): Rotates the whole log against a stationary knife, producing a continuous sheet with a distinct "cathedral" or "rotary cut" grain pattern. Maximizes yield from a log. Best for structural plies and consistent appearance.Slicer: Moves a stationary flitch (half-log or quarter-log) vertically or horizontally against a stationary knife, slicing off individual sheets. Produces veneer with the natural grain pattern of the log (flat cut, quarter cut, rift cut, crown cut). Used primarily for high-value decorative face veneers where specific grain aesthetics are paramount. Yield per log is lower than peeling.

- Q: What are the main operational challenges and maintenance needs of a wood peeler?A:High Wear: Knives and pressure bars wear rapidly and require frequent sharpening/replacement (multiple times per shift).Precision Alignment: Chuck alignment, knife/pebble parallelism, and machine stability are critical for consistent thickness and quality; misalignment causes vibration and poor veneer.Log Handling & Centering: Efficient loading and precise centering of the log in the lathe are vital for yield and minimizing vibration.Conditioning Consistency: Ensuring logs are uniformly conditioned throughout is challenging but essential.Vibration Control: Heavy, high-speed rotation demands robust foundations and dynamic balancing.Core Ejection: Efficiently removing the small core after peeling without damaging the lathe or causing downtime.

Recommended products