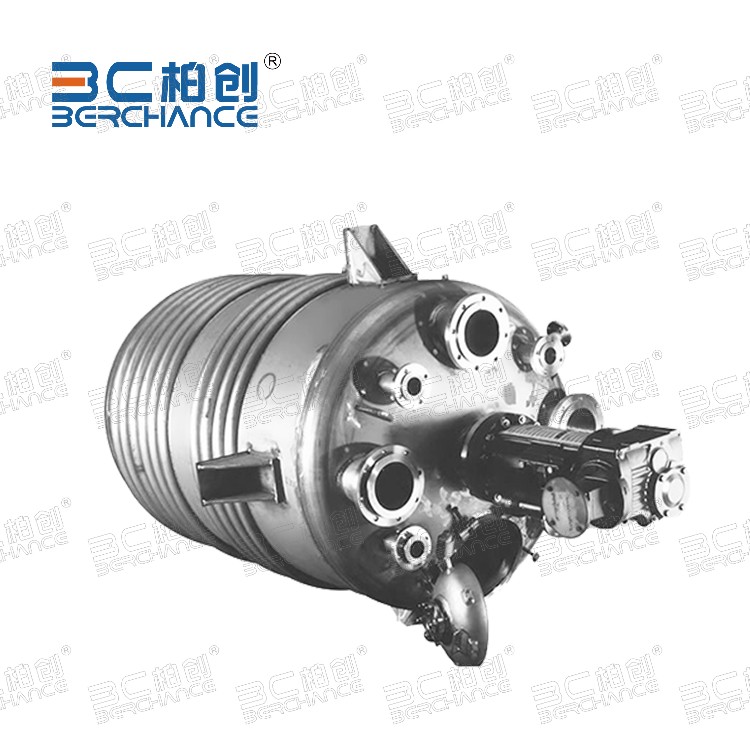

Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Product description

Product Overview:

The stainless steel mixing tank is designed for homogeneous mixing, blending, and emulsifying of liquids and semi-solids. It is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and biotechnology. The tank can be equipped with various types of agitators to meet different process needs, including anchor, paddle, turbine, and high-shear mixers.

Key Features:

- Material Options: Made of food-grade 304 or corrosion-resistant 316L stainless steel.

- Custom Agitators: Agitation structure customizable to fit viscosity and mixing objectives.

- Hygienic Design: Mirror-polished interior with CIP/SIP cleaning options, meeting GMP standards.

- Temperature Control: Available with jacketed structure for heating/cooling using steam, water, or thermal oil.

- Capacity Range: Available in volumes from 100L to 30,000L or more, with customization supported.

- Optional Automation: Supports temperature sensors, level gauges, frequency converters, and PLC control.

Applications:

- Food: dairy, sauces, beverages, flavorings

- Cosmetics: creams, lotions, serums

- Chemicals: paints, adhesives, detergents

- Pharmaceuticals: liquid formulations, herbal extractions

Recommended products