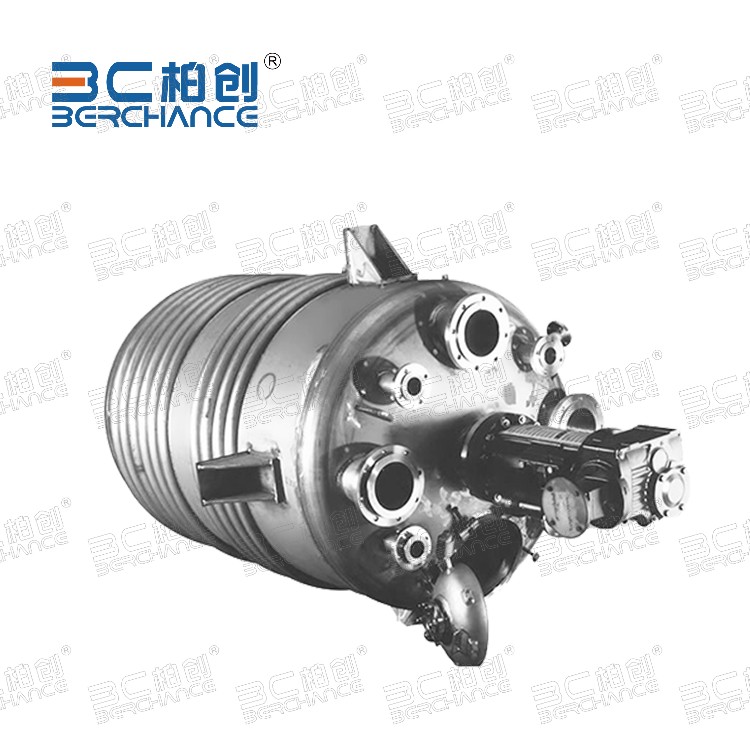

High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries

Product description

Product Overview:

The stainless steel heat exchanger is a vital component in thermal energy transfer systems, designed to efficiently transfer heat between two or more fluids without mixing them. Widely used in the chemical, pharmaceutical, dairy, beverage, and energy sectors, this equipment is engineered for reliability, hygiene, and high thermal conductivity.

Key Features:

- Durable Materials: Constructed with high-grade 304 or 316L stainless steel for corrosion resistance and long service life.

- High Heat Transfer Efficiency: Optimized shell-and-tube or plate-type configurations to ensure fast and efficient heat exchange.

- Hygienic & Cleanable: Internal surfaces polished and designed for easy CIP (Clean-in-Place) maintenance.

- Customizable Options: Support for single or multi-pass design, pressure ratings, and thermal control interfaces.

- Wide Temperature Range: Suitable for use in high-temperature and cryogenic applications.

- Energy-Saving Performance: Helps reduce fuel or power consumption through optimized thermal transfer.

Applications:

- Process cooling and heating in chemical plants

- Pasteurization and sterilization in food & dairy

- Steam condensation and hot water recovery

- Pharmaceutical production lines requiring temperature control

- HVAC systems and industrial refrigeration

Recommended products