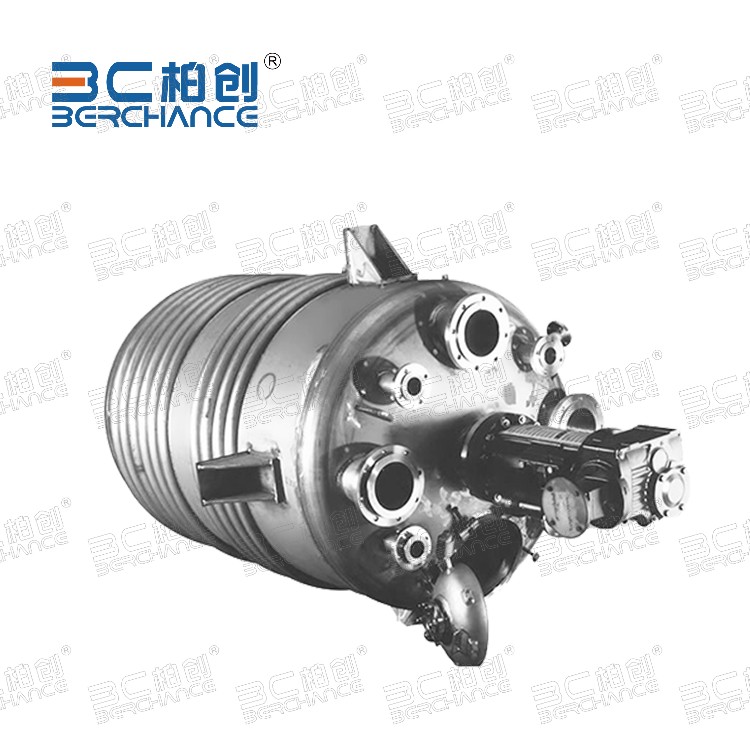

Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries

Product description

Product Overview:

The stainless steel fermentation tank is designed for microbial fermentation processes in industries such as biotechnology, pharmaceuticals, dairy, brewing, and food production. Equipped with advanced temperature, pH, and dissolved oxygen control systems, it ensures high-efficiency fermentation and product consistency.

Key Features:

- Sanitary Design: Made from 304/316L stainless steel with mirror-polished surfaces and CIP/SIP cleaning systems.

- Precision Control: Integrated temperature, pH, and agitation controls to maintain optimal fermentation conditions.

- Efficient Agitation: Customizable stirring system (top or bottom entry) for aerobic and anaerobic fermentation.

- Thermal Regulation: Jacketed or coil-type designs available for precise cooling and heating.

- Modular & Scalable: Volumes range from laboratory scale (5L) to industrial scale (30,000L+).

- GMP & FDA Compliant: Suitable for pharmaceutical-grade production with full documentation support.

Applications:

- Pharmaceutical fermentation (antibiotics, enzymes, vaccines)

- Food fermentation (yogurt, vinegar, pickles, soy sauce)

- Brewery and beverage industry (beer, wine, kombucha)

- Biotech R&D and scale-up production

Recommended products