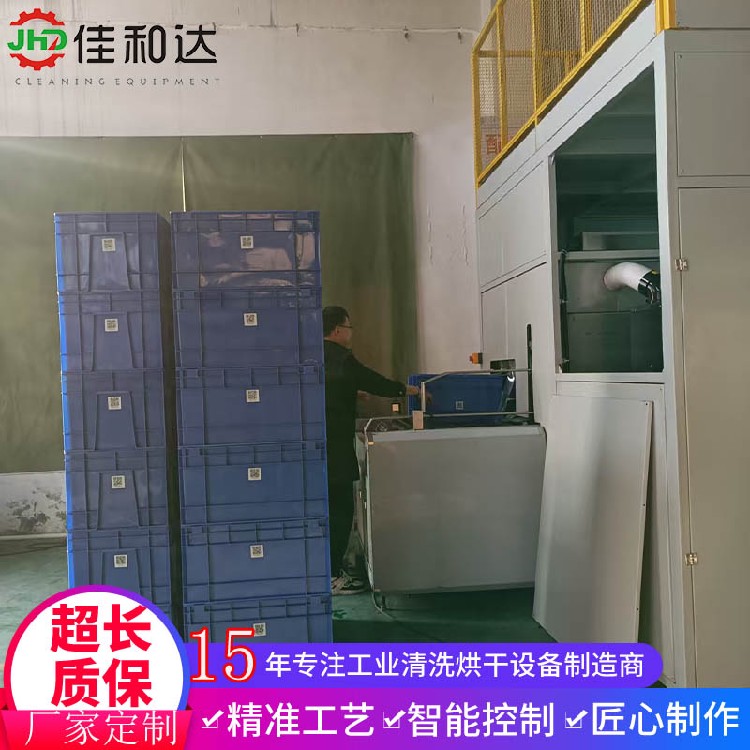

Single-slot machine with lifting and throwing

Product description

I. Product Overview

Single-slot ultrasonic cleaning machine (with lifting and throwing function) is a high-efficiency industrial cleaning equipment integrating ultrasonic cleaning and mechanical throwing. It realizes the efficient *** cleaning of complex structures and precision parts through the high-frequency ultrasonic cavitation effect combined with the programmable lifting and throwing system. It is widely used in the high-standard cleaning needs of electronics, medical, automobile, optics, *** and other industries.

II. Core structure and working principle

1. Main components

Component Function Description

The ultrasonic generator provides high-frequency electrical signals (28kHz/40kHz/80kHz) and drives the transducer to generate ultrasound.

Stainless steel cleaning tank made of 304/316 stainless steel, corrosion-resistant, can be customized in size (such as 10L-100L).

Lifting mechanism Electric/pneumatic lifting, adjustable stroke (0-300mm), smooth lifting cleaning basket.

Throwing system Variable frequency motor drive, supporting up and down/left and right/rotating throwing (10-30 times/minute).

Control system PLC/touch screen control, programmable cleaning process (time, temperature, throwing mode).

Heating system (optional) constant temperature control (RT-80℃) to improve the activity of the cleaning agent.

Filtration circulation system (optional) extends the life of cleaning liquid and reduces pollution.

2. Operating principle

1. Ultrasonic cleaning: High-frequency ultrasound produces catitized bubbles in the liquid, releases impact force when bursting, and peels off stains.

2. Lifting and throwing assistance:

Lifting: The workpiece immerses/leaves the cleaning solution to avoid long-term soaking damage.

Throwing: Mechanical movement makes the workpiece dynamically displaced in the liquid and eliminates the cleaning blind spot.

3. Multi-stage cleaning (optional): support the fully automated process of "ultrasonic + throwing + spraying + drying".

III. Technical parameters (examples of typical models)

Project Parameters

Ultrasonic frequency 28kHz/40kHz/80kHz (optional) Cleaning tank volume 15L/30L/50L (customizable)

Lifting stroke 0-200mm (electric adjustment)

Throwing mode Up and down/left and right/rotation (speed adjustable)

Power 600W-3000W (depends on the capacity)

Power supply 220V/50Hz or 380V (industrial grade)

IV. Detailed explanation of industry application

1. Electronic industry

Applicable parts: PCB board, connector, semiconductor wafer.

Cleaning requirements: remove flux, ion pollution and dust.

Advantages: Throwing prevents the component from sticking to the wall and avoids the ultrasonic shadow area.

2. Automobile manufacturing

Applicable parts: fuel nozzles, gearbox gears, brake parts.

Cleaning requirements: remove oil stains, metal debris, polishing paste.

Advantages: *** Throwing copes with deep holes and threaded structures.

V. Summary of product advantages

1. Upgrade the cleaning effect

Blind area zeroing: throwing + ultrasonic combination, the cleaning effect is more than 50% better than that of traditional equipment.

Uniformity guarantee: avoid uneven cleaning caused by stacking of workpieces.

2. Intelligent operation

Programmable control: store multiple sets of process formulas (such as "5-minute ultrasound + 2-minute throw").

Safety protection: overtemperature alarm, leakage protection, emergency braking.

3. Economic and environmental protection

Energy-saving design: the frequency converter adjusts the power, which saves 20% of power than fixed frequency equipment.

Circulation filtration: reduce the frequency of cleaning liquid replacement and reduce the cost of waste liquid treatment.

4. High compatibility

Material adaptation: metal, plastic and ceramics can be cleaned.

Industry customization: explosion-proof, anti-static, inert gas protection and other special configurations can be selected.

VI. Selection and service

Selection Guide: Select the frequency and tank volume according to the size of the workpiece and the type of pollution.

Support: Provide equipment debugging, process verification, consumables (cleaning agent/filter).

VII. Summary

Through the innovative design of "ultrasonic + dynamic throwing", this equipment solves the core pain points of the high-precision cleaning industry. It has the three characteristics of high efficiency, intelligence and environmental protection, and is an ideal choice to replace manual cleaning and multi-channel assembly lines. Support non-standard customization to meet the strict cleaning needs of special industries.

If you need specific model parameters or industry solutions, welcome to consult for further consultation!

Recommended products