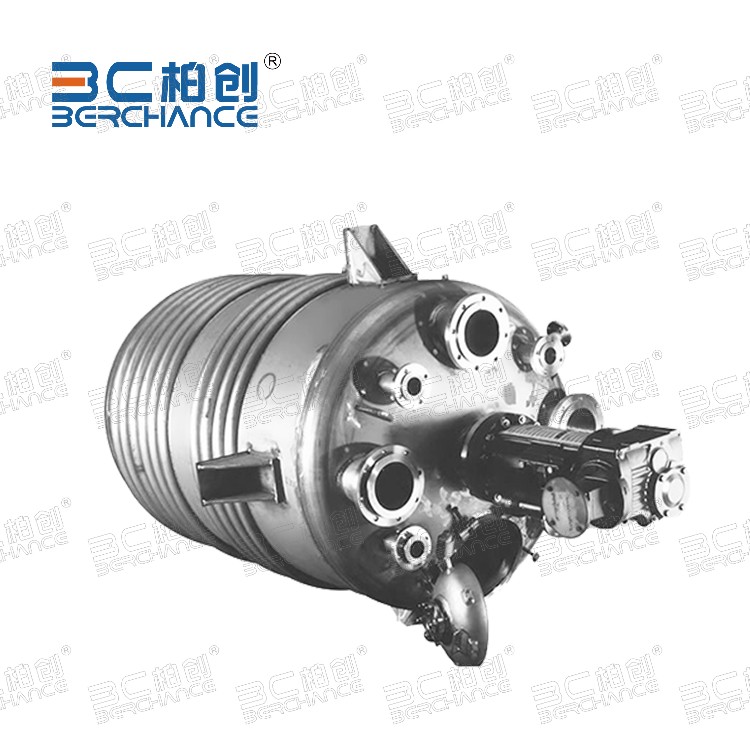

China Suppliers Double Jacket Electric/Steam Heating Pressure Liquid Blending Reaction Kettle

Product description

Distillation kettle, as one of the core equipment in chemical separation technology, plays an important role in the chemical industry. With the continuous advancement and innovation of technology, the performance and functionality of distillation vessels will be further improved and perfected. In the future, distillation vessels will continue to play an important role in pharmaceutical, chemical, food and other fields, providing more efficient, environmentally friendly and safe solutions for chemical production.

A distillation kettle usually consists of the following main parts: kettle body, heater, condenser, receiver, and necessary pipelines and valves. The kettle body is generally made of corrosion-resistant materials, such as stainless steel or fiberglass, to withstand the pressure and temperature generated during the heating process. The heater is responsible for providing heat to bring the mixture to a boiling state. The condenser is used to cool the generated steam into liquid form for easy collection. The receiver is used to receive and store the separated components. In addition, the distillation kettle is equipped with temperature, pressure and other monitoring instruments to ensure the safety and stability of the operation process.

Reaction vessels are widely used in industries such as petroleum, chemical, rubber, pesticides, dyes, pharmaceuticals, and food. In these industries, reaction vessels are used to complete processes such as sulfurization, nitration, hydrogenation, alkylation, polymerization, and condensation. For example, in the pharmaceutical industry, reaction vessels are used as critical steps in drug synthesis processes; In the chemical industry, it is used for the synthesis and purification of various chemicals.

Distillation kettle is one of the indispensable and important equipment in chemical production, with a compact structure, easy operation, good separation effect, and a wide range of applications. With the continuous advancement of technology and the expansion of application fields, the performance and functionality of distillation kettles will also be further improved and perfected. The distillation kettle converts electrical energy into thermal energy to heat materials, which has the advantages of easy cleaning, high efficiency (with an electrical energy utilization rate of over 95%), heating temperature of over 3000 ℃, and easy adjustment.

Recommended products