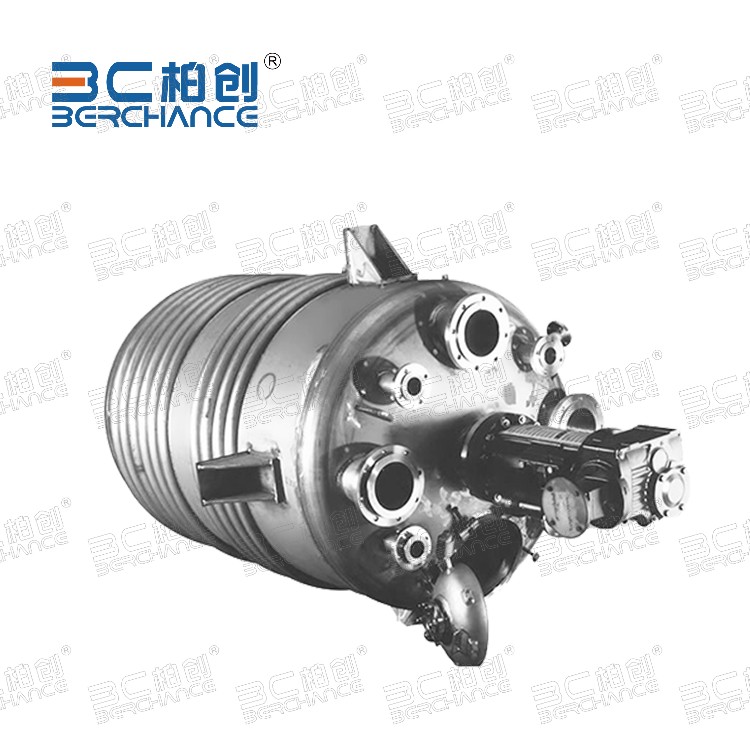

Stainless Steel (SS) Double Jacket Electric/Steam Heating Pressure Liquid Blending Reaction Kettle

Product description

Maintenance and upkeep

Strictly follow operating procedures and safety regulations to ensure the safety of operators.

Regularly inspect and maintain all equipment and accessories of the reactor to ensure its normal operation and extend its service life.

Pay attention to changes in temperature, pressure, and other parameters during the reaction process, and adjust control parameters in a timely manner to maintain a stable production process.

During shutdown or maintenance, it is necessary to follow the prescribed procedures for emptying, cleaning, and maintenance to ensure the good condition of the equipment.

The distillation kettle has the advantages of simple structure, convenient operation, and good separation effect. Meanwhile, with the continuous advancement of technology, modern distillation kettles have also achieved higher levels of automation and a wider range of applications. In order to solve the problem of intermittent maintenance and cleaning of solid and high boiling point substances in the production process of traditional distillation kettles, modern distillation kettles have made many improvements in design, such as adding devices such as demisters and settling chambers, to improve production efficiency and product quality.

Recommended products