Unlock the Power of Efficient Tree Debarking: A Complete Guide to Tree Debarkers

Product description

Understanding Tree Debarkers: An Essential Tool for Forestry and Industry

Tree debarkers are specialized machines designed to remove bark from logs quickly and efficiently. Whether you're a forestry professional, timber processor, or involved in wood production, a high-quality debarking solution can dramatically improve your workflow, enhance wood quality, and reduce operational costs. These machines are engineered to handle a variety of tree sizes and species, making them versatile tools across different applications. With rapid bark removal, they facilitate easier handling, transportation, and further processing of logs, leading to more uniform and higher-value lumber.

Core Features and Advantages of Tree Debarkers

1. Durability and Power: Most tree debarkers are built with rugged materials like steel and feature powerful engines that can cope with dense bark and large logs, ensuring longevity even in demanding environments.

2. Adjustable Settings: Modern debarking machines often come with adjustable infeed and outfeed systems, allowing operators to fine-tune settings based on log size, shape, and bark type. This customization maximizes efficiency and minimizes waste.

3. Speed and Efficiency: Debarkers significantly outpace manual bark removal methods, processing logs at high speeds to meet industry demands. Their automation reduces labor costs, minimizes processing time, and enhances productivity.

4. Quality of Debarking: A key advantage is the superior clean removal of bark, which improves the quality of the final timber. Proper debarking reduces the risk of defects, pests, and fungal contamination in the remaining wood.

5. Eco-friendly Operation: Many modern debarkers are designed to be energy-efficient and produce minimal waste, aligning with sustainable practices in forestry and timber processing industries.

Main Applications and Industry Uses

1. Forestry Harvesting: Debarkers are indispensable during timber harvesting, preparing logs for storage, transport, or sawing. They facilitate handling and help maintain log integrity.

2. Lumber Mills: In sawmills, debarking is a crucial initial process, ensuring that logs are clean and ready for cutting, which helps prevent equipment wear and improves the quality of sawn timber.

3. Biomass and Pulp Production: Clean logs are essential in pulp and biomass industries to avoid contamination and machinery damage, making debarkers a vital step in processing.

4. Landscaping and Firewood: For firewood producers and landscapers, debarkers help produce cleaner and easier-to-split logs, enhancing safety and handling.

User FAQs - All You Need to Know about Tree Debarkers

Q1: How does a tree debarker work?

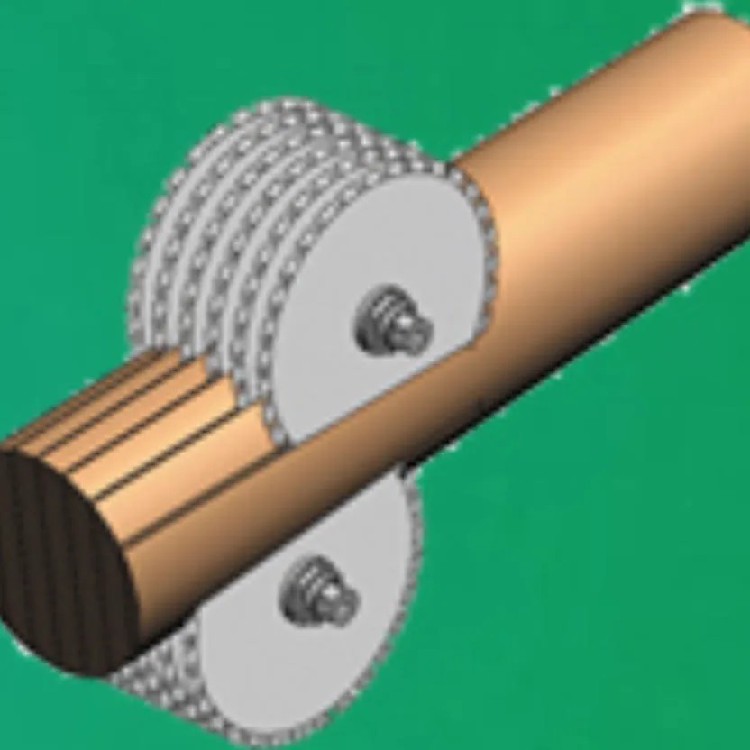

A1: A tree debarker operates by feeding logs into a rotating drum or wheel, equipped with blades or brushes that peel away bark efficiently. The process involves mechanical contact that loosens and strips bark without damaging the underlying wood, allowing for quick processing of large volumes of timber.

Q2: What types of logs can a debarker handle?

A2: Tree debarkers are designed to handle a broad range of logs from small diameter saplings to large and thick-trunked trees. They are adaptable to various species, depending on the hardness and bark texture, making them suitable for diverse forestry and industrial needs.

Q3: Is a tree debarker suitable for small-scale operations?

A3: While debarkers are primarily used in large-scale industrial settings, smaller and more portable models are available for strategic use in small-scale or specialty operations, providing flexibility and efficiency at different levels of production.

Q4: What maintenance does a tree debarker require?

A4: Regular maintenance includes checking and sharpening blades or brushes, lubricating moving parts, inspecting belts and chains, and ensuring that electronic controls are functioning smoothly. Proper maintenance prolongs lifespan and assures consistent performance.

Q5: How does a debarking machine contribute to sustainability?

A5: By producing clean and uniform logs, debarkers reduce waste during subsequent processing. They also help prevent damage from bark pests and fungal infestations, supporting forest health and reducing the need for chemical treatments, thus promoting sustainable practices.

Final Thoughts: Elevate Your Wood Processing with a Tree Debarker

Investing in a reliable tree debarker can transform your operations, leading to higher quality output, boosted efficiency, and lower costs. These machines are adaptable, robust, and designed to meet the needs of modern forestry and wood processing industries. Whether handling large commercial timber or supporting specialized niche operations, a top-tier debarking solution offers a significant competitive edge. Embrace this technology to streamline your workflow, enhance product quality, and contribute to sustainable forestry practices.

Recommended products