Tree Debarkers: Revolutionizing Wood Processing Efficiency

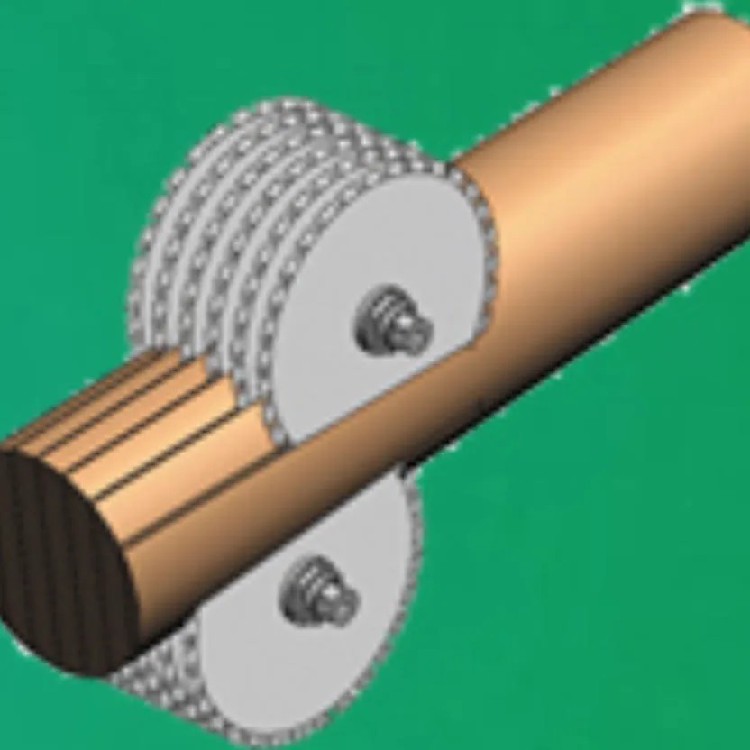

Product description

Tree debarkers are essential tools in the wood processing industry, designed to remove the bark from logs with precision and efficiency. Whether you are in the timber, paper, or furniture industry, a high-quality debarker is crucial for improving productivity, reducing costs, and enhancing the quality of finished products. In this article, we will explore the core features, benefits, and applications of tree debarkers, along with answers to some frequently asked questions.

Core Features of Tree Debarkers

Tree debarkers come in various designs, but they all share a few key features that ensure optimal performance:

1. Effective Bark Removal: A tree debarker is built to remove the bark from the tree with minimal damage to the underlying wood. This is vital for industries such as pulp and paper production, where the quality of the raw material plays a direct role in the final product.

2. Durable Construction: These machines are built to withstand the harsh conditions of a wood-processing environment. Most debarkers feature heavy-duty materials like hardened steel and robust motors to ensure longevity and minimal downtime.

3. Adjustable Settings: Modern debarkers often come with adjustable settings that allow operators to control the level of bark removal. This flexibility ensures that the process is tailored to specific types of wood or project requirements.

4. High Efficiency: With advanced technology, tree debarkers operate with high throughput rates, reducing the time needed to process logs. This leads to increased production capacity and improved operational efficiency.

5. Safety Features: To ensure the safety of operators, tree debarkers are equipped with safety mechanisms such as emergency stop buttons, protective covers, and automated systems to handle unforeseen issues.

Key Advantages of Using Tree Debarkers

1. Increased Productivity: By automating the bark removal process, tree debarkers help speed up the initial stages of wood processing. This reduces manual labor and minimizes the time it takes to prepare logs for further use.

2. Enhanced Quality Control: Bark-free logs are essential for creating high-quality wood products. Whether it’s for paper production, lumber, or furniture making, removing the bark ensures a smoother, cleaner finish and reduces the risk of imperfections in the final product.

3. Cost Efficiency: By streamlining the process and reducing waste, tree debarkers can help businesses lower their operating costs. Furthermore, with less bark to dispose of, companies save on waste management expenses.

4. Environmental Benefits: Tree debarkers often produce very little waste, as the bark is removed and collected for further use. This contributes to a more sustainable production process.

Applications of Tree Debarkers

Tree debarkers are used across various industries, each benefiting from the efficient and clean bark removal process. The main applications include:

1. Pulp and Paper Industry: In paper manufacturing, the quality of wood used is crucial. Bark-free logs are required to prevent contamination during the pulping process, resulting in higher quality paper products.

2. Lumber and Sawmills: Logs processed through a debarker are better suited for cutting into high-quality lumber, as the absence of bark helps prevent damage to cutting tools and ensures smoother processing.

3. Furniture Manufacturing: When making furniture, removing the bark allows manufacturers to create a more polished and uniform finish on wooden products, enhancing their aesthetic appeal.

4. Biomass Energy Production: In some regions, tree bark is collected and used as biomass fuel. Tree debarkers help make this process more efficient by ensuring that only the wood, rather than mixed materials, is used in energy production.

Frequently Asked Questions About Tree Debarkers

1. What types of logs can a tree debarker handle?

Tree debarkers are versatile and can handle a variety of logs, including hardwoods and softwoods. However, the effectiveness of bark removal depends on the size, type, and condition of the logs.

2. How do I maintain a tree debarker?

Regular maintenance is essential to ensure optimal performance. This includes checking the sharpness of the blades, lubricating moving parts, and cleaning the machine to remove debris or build-up that may interfere with operation.

3. Is a tree debarker environmentally friendly?

Yes, tree debarkers are designed to minimize waste. The bark is typically collected and repurposed either for biomass energy or as a byproduct for other industrial uses.

4. How fast can a tree debarker process logs?

The processing speed of a tree debarker depends on its design and the type of logs being used. Some debarkers can process logs at speeds of several meters per minute, ensuring high throughput.

5. What safety precautions should I take when using a tree debarker?

Operators should always follow manufacturer guidelines and wear appropriate protective equipment. It is also important to regularly inspect the machine for wear and tear to prevent accidents.

Conclusion

Tree debarkers are indispensable tools in the wood processing industry, offering substantial benefits in terms of productivity, cost-efficiency, and quality control. By automating bark removal, businesses can streamline their operations and produce higher-quality wood products while minimizing waste. With proper maintenance and care, a tree debarker can significantly enhance the efficiency of any wood-processing operation. Whether you're in the paper, lumber, or biomass industry, investing in a high-quality tree debarker is a smart choice for sustainable growth and improved performance.

Recommended products