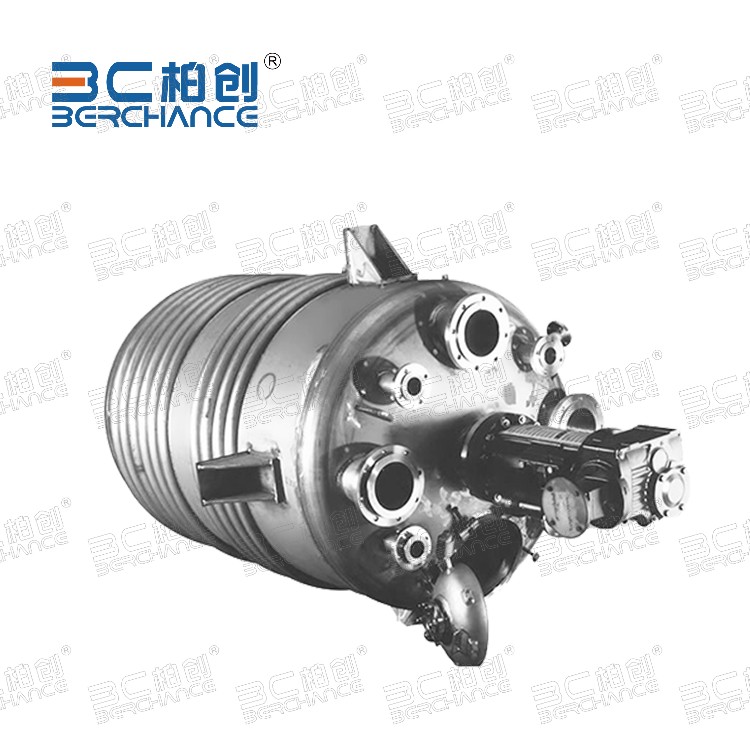

Good Quality 304 316 316L 310S 347H 2205 2507 904L Fabricated High Chemical Reaction Kettle

Product description

component

Shell: usually cylindrical or spherical, lined with corrosion-resistant materials such as stainless steel or fiberglass to withstand the pressure and temperature generated during the heating process.

Heater: Used to provide energy to boil a mixture, common types of heaters include electric heaters, steam heaters, and organic heat carrier heaters.

Condenser: cools the generated steam into liquid form for collection.

Receiver: used to collect liquid products of different components.

Inlet and outlet: used for adding the mixture to be processed and removing the separated product, respectively.

Distillation kettle is a widely used equipment in chemical production, mainly used to separate liquid mixtures into different components by distillation. A distillation kettle is a specialized equipment used for distillation in chemical production, which separates the components of a liquid mixture according to their boiling points by heating. Based on the difference in boiling points of each component in a liquid mixture, the low boiling components are first vaporized by heating, and then condensed into liquid by a condenser to achieve component separation.

Recommended products